Fully Automatic Egg Tray Machine for Efficient Waste Paper Recycling

One-step forming process reduces production costs by 30%

Successfully served over 100 customers worldwide

Pulp Molding Production Lines & Egg Tray Machines

Discover our range of high-quality pulp molding machines designed for efficiency, durability, and exceptional performance in egg tray manufacturing

Our Product Series

Richon Group offers four main series of pulp molding machines, each designed to meet specific production needs and capacity requirements.

REM Automatic Production Line

- Capacity: 2000-9000 pcs/h

- Fully automatic operation

- Energy saving: 30% less consumption

- PLC intelligent control system

- Low maintenance design

REM Semi-Automatic Production Line

- Capacity: 1000-2500 pcs/h

- 2-3 operators required

- Compact design

- Cost-effective solution

- Easy to upgrade to full automation

RPM Automatic Production Line

- Capacity: 500-8000 pcs/h

- Advanced robotic integration

- Precision molding technology

- IoT connectivity for remote monitoring

- Quick mold change system

RCM Automatic Production Line

- Capacity: 2000-12000 pcs/h

- Ultra-high speed production

- Premium quality output

- AI-powered optimization

- Advanced safety features

Applications

Our pulp molding machines are versatile and can be used to produce a wide range of packaging products for various industries.

Egg Packaging

Produce high-quality egg trays for poultry farms and egg processing facilities with various capacities.

Fruit Trays

Manufacture protective trays for fruits like apples, pears, and citrus fruits to prevent damage during transport.

Coffee Cup Holders

Create eco-friendly coffee cup trays and holders for the food service industry.

Industrial Packaging

Produce protective packaging for electronics, glassware, and other fragile industrial products.

Technical Advantages

Our pulp molding machines incorporate advanced technologies that provide significant benefits over traditional manufacturing methods.

Environmental Sustainability

Our machines use recycled paper as raw material, creating biodegradable products that reduce environmental impact and support circular economy initiatives.

Energy Efficiency

Advanced drying systems and optimized production processes reduce energy consumption by up to 30% compared to conventional methods.

Automation & Precision

PLC control systems and precision molding technology ensure consistent product quality and reduce labor requirements.

Quick Mold Change

Our machines feature quick mold change systems that allow for flexible production of different product types with minimal downtime.

Smart Technology

IoT connectivity and AI-powered optimization enable remote monitoring and predictive maintenance for maximum uptime.

Enhanced Safety

Comprehensive safety features and emergency stop systems protect operators and ensure compliant operation.

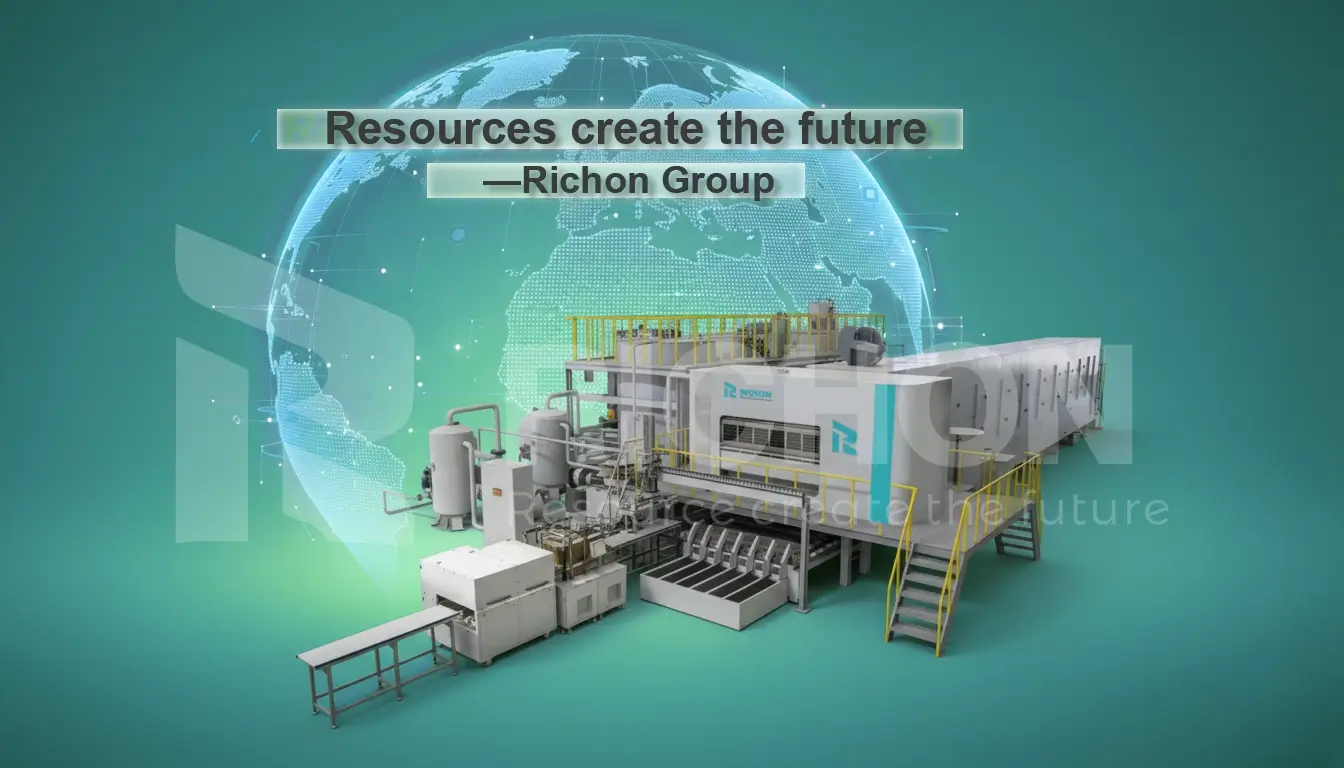

Professional Pulp Molding Machine Manufacturer

Industry Experience

Richon Group specializes in designing and manufacturing high-quality pulp molding machines for egg tray production. Our machines are engineered for maximum efficiency, durability, and environmental sustainability. With over 25 years of experience in the industry, we provide innovative solutions that help businesses increase productivity while reducing operational costs.

Product Range

Our product range includes fully automatic and semi-automatic production lines capable of manufacturing various types of pulp molded products, including egg trays, fruit trays, and industrial packaging. All our pulp molding machines are designed with energy-saving features and utilize advanced technology to ensure consistent product quality and minimal waste.

Customized Solutions

Whether you’re establishing a new production facility or upgrading existing equipment, our technical team can provide customized solutions tailored to your specific requirements. Contact us today to learn more about how our pulp molding machines can benefit your business.

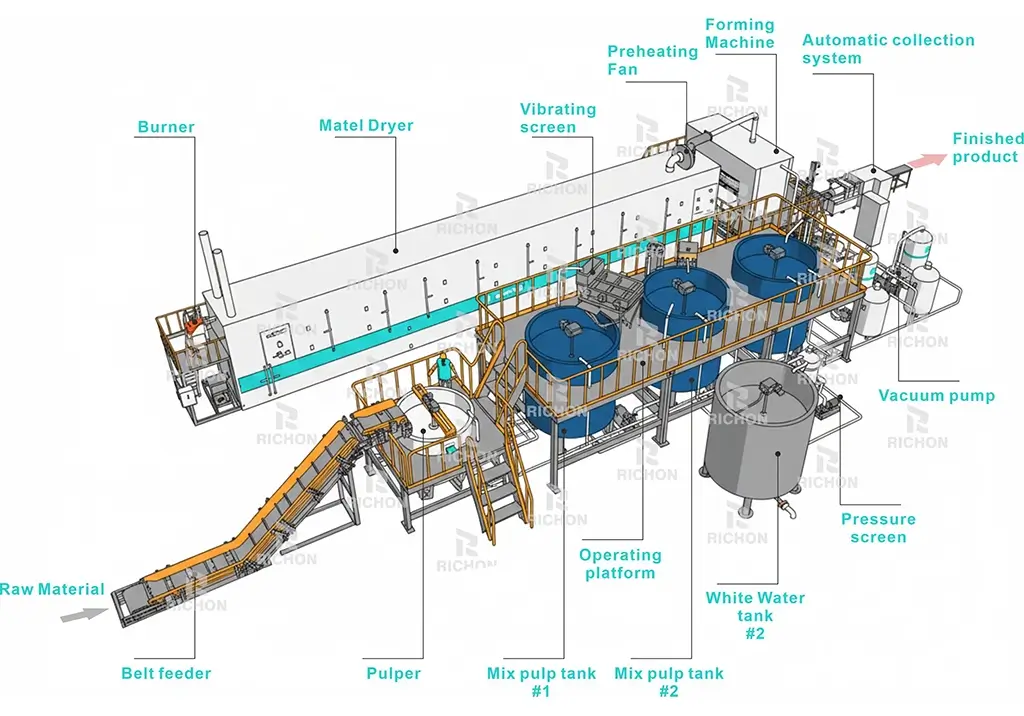

Complete Production Line Overview

Our fully integrated pulp molding production lines are designed for maximum efficiency and output quality. The diagram below illustrates the complete workflow from raw material input to finished product packaging.

Production Process Flow

Key Production Steps

Raw Material Processing

Waste paper is pulped and prepared for molding, ensuring consistent quality and optimal material utilization.

Automatic Molding

Advanced molding systems form precise egg tray shapes with minimal human intervention and maximum efficiency.

Energy-Efficient Drying

Multi-stage drying systems remove moisture while conserving energy through heat recovery technology.

Automated Packaging

Finished products are automatically counted, stacked, and packaged for shipment, reducing labor costs.

Environmental Benefits of Pulp Molding Machines

Pulp molding technology represents a sustainable alternative to traditional packaging materials, offering significant environmental advantages while maintaining high performance standards for egg tray production and other packaging applications.

Core Environmental Advantages

Waste to Value

Transform waste paper into high-value molded products, reducing landfill pressure and enabling a circular economy.

Plastic Alternative

Eco-friendly substitute for single-use plastics, aligned with global bans and buyer preferences in EU/US markets.

Energy & Resource Efficiency

Save up to 20% energy with optimized drying; closed-loop water systems minimize consumption and discharge.

Sustainable Business Growth

Meet ESG goals, strengthen brand reputation, and win more contracts with verifiable green packaging.

Quantifiable Environmental Impact

Industry Transition Trends

Environmental Certifications

ISO 14001

International standard for effective environmental management systems.

FSC Certified

Ensures responsible sourcing of paper and pulp materials.

Recyclability Compliance

Meets international recycling and biodegradability criteria for eco-friendly packaging.

EU Environmental Standards

Complies with EU packaging waste regulations and sustainability directives.

Pulp molding technology delivers a measurable and scalable environmental benefit while supporting a global shift toward sustainable packaging. Choosing pulp molding machines is not just a business upgrade—it is an investment in a cleaner future.

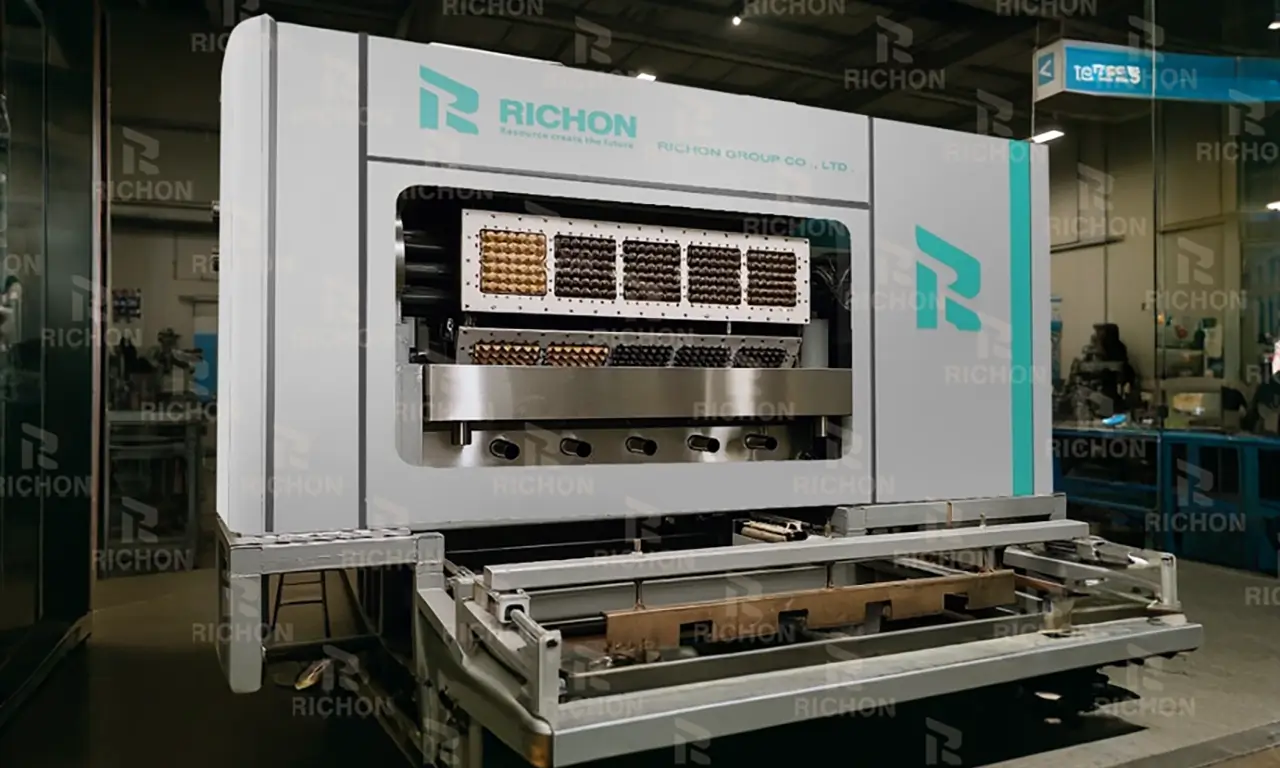

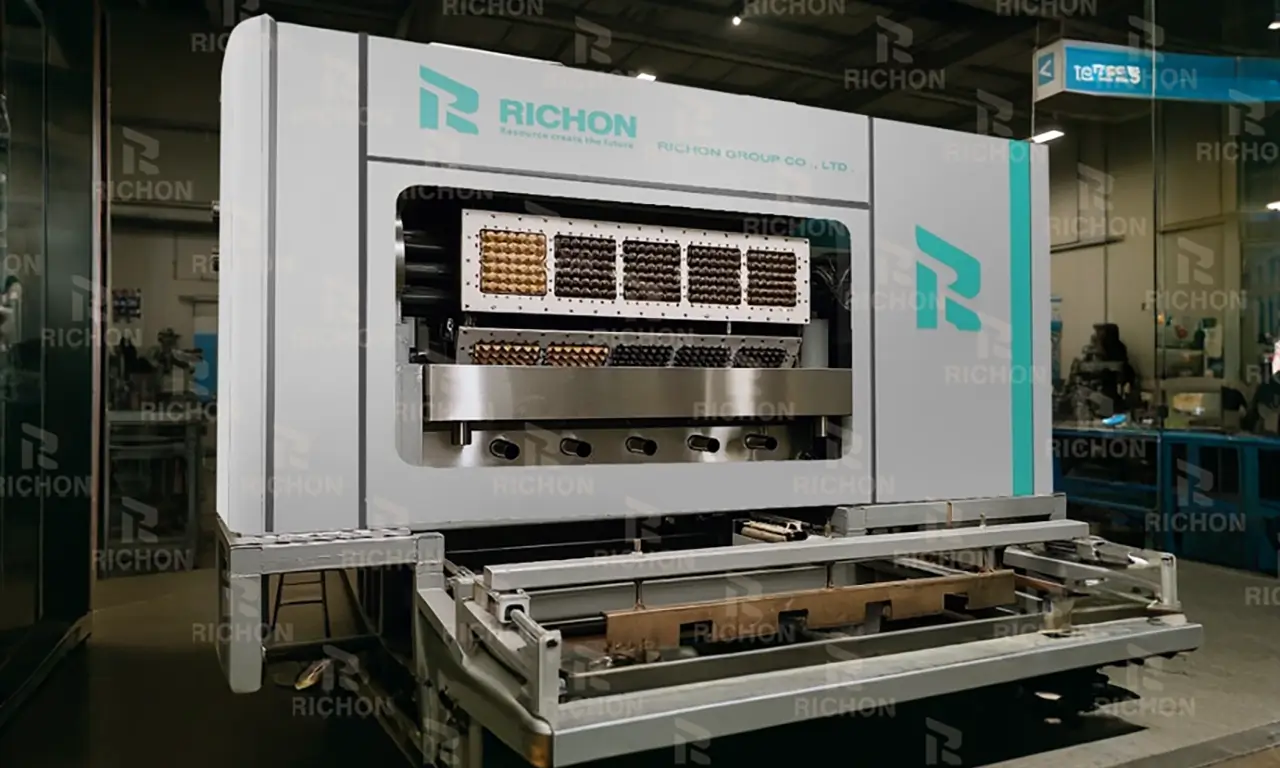

Egg Tray Machine Production Capacity & Mold Configuration

Learn how mold plate sides, molds per side, and overall machine configuration impact the production efficiency of Richon automatic egg tray machines.

Impact of Mold Plate Design

The production capacity depends on the mold plate design, specifically the number of sides and the number of molds installed per side. Optimized design ensures higher output efficiency.

Richon egg tray machines offer mold plates with 1 to 8 sides, each side holding 3 to 10 egg tray molds, providing flexible production scaling.

More Molds, Higher Output

Increasing the number of molds directly boosts production capacity. This enables operators to meet higher market demand without compromising quality.

Choosing the Right Configuration

Selecting the appropriate machine configuration ensures cost-effectiveness and optimal ROI. Richon provides custom solutions tailored to your production needs.

Example: 4000 pcs/hour Automatic Egg Tray Machine

Key Specifications

Mold Plate Sides

1 to 8 sides, allowing scalable production capacity.

Molds per Side

Each side holds 3 to 10 molds, maximizing efficiency.

Scalable Output

Output capacity can be adjusted based on mold quantity.

Customized Solutions

Tailored machine configurations for specific production requirements.

Egg Tray Production Process Flow

Our advanced pulp molding technology transforms recycled paper into high-quality egg trays through an efficient, environmentally friendly process

Production Process Overview

The pulp molding process transforms recycled paper into protective egg trays through six key stages, combining advanced technology with environmental sustainability to create high-quality, biodegradable packaging solutions.

Raw Material Preparation

We source high-quality recycled paper materials, primarily old newspapers and cartons, which are sorted and prepared for the pulping process. This ensures consistent quality and environmental sustainability.

- Carefully selected recycled paper sources

- Quality control and sorting process

- Environmental sustainability certification

- Consistent material quality assurance

Pulp Preparation

Recycled paper is mixed with water in a hydraulic pulper to create a uniform pulp mixture with the right consistency for molding. The pulp is refined and additives are introduced to enhance strength and quality.

- Automated mixing system ensures consistency

- Precise control of pulp density and viscosity

- Water recycling system reduces waste

- Quality additives for enhanced durability

Molding Process

The prepared pulp is transferred to forming molds where vacuum suction forms the egg tray shape and removes excess water. This creates the basic structure of the egg trays with precise dimensions.

- Precision molding ensures accurate shape

- Quick forming increases production efficiency

- Efficient dewatering reduces drying time

- Custom molds for different tray designs

Drying Process

Newly formed egg trays go through a multi-stage drying system to remove remaining moisture and strengthen the structure. Our energy-efficient drying technology ensures optimal moisture content.

- Energy-efficient drying system reduces consumption

- Uniform heat distribution ensures consistent quality

- Precise humidity control prevents over-drying

- Multi-zone temperature optimization

Fully Automatic Collection

Our advanced automated system collects, counts, and stacks finished egg trays with precision and efficiency. This process eliminates manual handling and ensures consistent quality throughout the production line.

- Robotic collection system ensures gentle handling

- High-precision counting for accurate batch sizes

- Automated stacking optimizes space utilization

- Quality inspection during collection process

Hot Pressing & Shaping

Trays undergo hot pressing to create smooth surfaces, precise shapes, and increased durability. This process enhances the structural integrity and gives the trays their final form.

- High-pressure forming enhances structural integrity

- Precise temperature control ensures consistency

- Uniform dimensions facilitate stacking and packaging

- Smooth surface finishing for better product presentation

Technical Advantages

Our pulp molding process incorporates advanced technologies that deliver significant benefits in efficiency, quality, and sustainability compared to traditional manufacturing methods.

Environmental Sustainability

Uses 100% recycled paper materials and produces fully biodegradable products, supporting circular economy principles and reducing plastic waste.

Energy Efficiency

Advanced drying systems and optimized production processes reduce energy consumption by up to 30% compared to conventional methods.

High Production Capacity

Automated systems enable production of 2,000-12,000 egg trays per hour depending on machine model and configuration.

Precision Engineering

PLC control systems and precision molding technology ensure consistent product quality and dimensional accuracy.

Production Specifications

Our pulp molding machines are available in various configurations to meet different production requirements and capacity needs.

Environmental Benefits & Sustainability

Environmental Leadership: Our entire production process is designed for maximum efficiency with minimal energy consumption. The system uses recycled water and produces zero waste, making it an environmentally friendly solution for egg packaging needs. All products are 100% biodegradable, helping to reduce plastic pollution and supporting circular economy principles.

By choosing pulp molded egg trays, businesses can reduce their carbon footprint, meet ESG goals, and respond to growing consumer demand for sustainable packaging solutions. Our technology transforms waste paper into valuable protective packaging, closing the loop in the paper lifecycle and contributing to a cleaner environment.

Egg Tray Machine Comparison

Compare specifications and performance metrics across our range of REM egg tray production machines to select the ideal model for your needs.

| Parameters / Models | REM3-1 | REM4-1 | REM3-4 | REM4-4 | REM4-8 | REM5-8 | REM6-8 | REM8-8 |

|---|---|---|---|---|---|---|---|---|

| Production Capacity | 800-1000 pcs/h | 1000-1500 pcs/h | 1700-2200 pcs/h | 2000-2800 pcs/h | 4000-4500 pcs/h | 5000-5500 pcs/h | 6000-6500 pcs/h | 8000-9000 pcs/h |

| Molding Stations | 3 | 4 | 12 | 16 | 32 | 40 | 48 | 64 |

| Total Power | 32 kW | 36-60 kW | 55-74 kW | 58-88 kW | 127-144 kW | 153-190 kW | 226-239 kW | 374kW |

| Power Consumption (70% of Total Power) | 22.4 kW | 25.2-42 kW | 38.5-51.8 kW | 40.6-61.6 kW | 88.9-100.8 kW | 107.1-133 kW | 158.2-167.3 kW | 261.94 kW |

| Labor Required | 3-5 person | 4-6 person | 4-6 person | 4-6 person | 4-6 person | 5-7 person | 6-8 person | 6-8 person |

| Material Consumption per Hour | ||||||||

| Paper Consumption (kg/h) | 64 | Nature drying/Drying: 96 Metal: 85 | Nature drying: 144 Drying: 160 | Drying/Nature drying: 200 Metal: 176 | 340 | 425 | 520 | 640 |

| Water Consumption (kg/h) | 160 | Air drying/Drying: 240 Metal: 212.5 | Air drying: 360 Drying: 400 | Drying/Air drying: 500 Metal: 440 | 850 | 1062.5 | 1300 | 1600 |

| Brick Drying Consumption per Hour | ||||||||

| Coal (kg/h) | 55-65 kg | 60-70 kg | 70-80 kg | 94-104 kg | 115-125 kg | 140-150 kg (Actual: 300-350 kg) | 170-180 kg | 230-240 kg |

| Natural Gas (m³/h) | 32-42 m³ | 38-48 m³ | 44-54 m³ | 60-70 m³ | 74-84 m³ | 92-102 m³ | 100-110 m³ | 130-140 m³ |

| LPG (L/h) | – | – | – | – | 98.28 L | 118.13 L | – | – |

| Diesel (kg/h) | 26-36 kg | 30-40 kg | 35-45 kg | 50-60 kg | 60-70 kg | 74-84 kg | 83-93 kg | – |

| Multi-layer Metal Drying Consumption per Hour | ||||||||

| Natural Gas (m³/h) | 25-35 m³ | 30-40 m³ | 35-45 m³ | 48-58 m³ | 60-70 m³ | 75-85 m³ | 90-100 m³ | 120-130 m³ |

| Diesel (kg/h) | 20-30 kg | 23-33 kg | 27-37 kg | 40-50 kg | 48-58 kg | 60-70 kg | 67-77 kg | 90-100 kg |

Note: Data is based on standard operating conditions. Actual performance may vary depending on materials, operational practices, and environmental factors.

Why Choose Us

With over two decades of expertise, we deliver exceptional pulp molding solutions that maximize efficiency and sustainability for your business.

Cost Savings

Our equipment reduces operational costs by up to 40% through energy efficiency and minimal maintenance requirements.

Efficient Production

High-speed automation capabilities ensure maximum output with consistent quality for your production needs.

Stable Quality

Precision engineering delivers uniform product quality with less than 0.5% defect rate in finished products.

Energy Saving

Innovative design reduces energy consumption by 30% compared to conventional pulp molding equipment.

Advanced Technology

Smart control systems with IoT integration for real-time monitoring and predictive maintenance capabilities.

25 Years Experience

Quarter-century of industry expertise ensures reliable solutions tailored to your specific requirements.

50+ Countries

Global presence with successful installations across six continents and comprehensive support network.

Quality After-Sales

24/7 technical support, remote assistance, and readily available spare parts anywhere in the world.

Egg Tray Making Machine Cases in the International Market

Discover our successful installations worldwide, showcasing high efficiency, reliability, and adaptability in diverse markets and climates.

Russian Egg Packaging Co.

Serving the expanding Russian egg market, this installation operates efficiently in cold climate conditions and has increased production capacity by 35%.

Key Features

Cameroon Poultry Solutions

Supporting the growing poultry industry in Central Africa, this installation provides affordable packaging solutions using locally sourced recycled materials.

Key Features

India Apple Tray Producers

Serving one of the world's largest egg markets, this installation efficiently handles high-volume production while adapting to diverse local climate conditions and material availability.

Key Features

Egg Tray Machine FAQ

Find answers to common questions about our egg tray making machines and services.

What is the production capacity of your egg tray machines?

Our egg tray machines range from 1,000 to 10,000 pieces per hour, depending on the model and configuration. REM4 series typically produces 2,000–4,500 pcs/hour, and high-capacity REM8 models reach up to 8,000–10,000 pcs/hour.

What raw materials are required for production?

Our machines primarily use waste paper such as newspaper, cardboard, office paper, and other paper waste. The pulp molding process is chemical-free and environmentally friendly.

How long does installation and training take?

Installation typically takes 2-9 weeks depending on the machine model and site conditions. We provide comprehensive training for 1-2 weeks to ensure your team can operate the machine efficiently. Ongoing remote support is available as needed.

What is the power consumption of your machines?

Power consumption varies by model. Our standard REM4-4 model consumes approximately 25-30 kW, while larger models like the REM8-8 consume around 60-75 kW. All our machines are designed with energy efficiency in mind, featuring optimized drying systems and energy recovery options.

Do you provide after-sales support and spare parts?

Yes, we offer comprehensive after-sales support including technical assistance, remote troubleshooting, and a global supply chain for spare parts. We maintain regional service centers to ensure quick response times and minimal downtime for our clients worldwide.

What is the typical ROI for an egg tray machine investment?

The return on investment typically ranges from 12 to 24 months, depending on production capacity, raw material costs, and local market conditions. Our smaller machines can pay for themselves in as little as 12 months, while larger installations may take up to 24 months.

Can your machines produce other products besides egg trays?

Yes, with different molds, our machines can produce various paper packaging products including fruit trays, cup carriers, bottle separators, and electronic packaging. We offer custom mold design services to meet your specific product requirements.

What is the warranty period for your machines?

We offer a 12-month warranty on all our machines, covering manufacturing defects and component failures. Extended warranty options are available for critical components. Our warranty includes technical support and replacement of defective parts.

Contact Us

Get in touch with our team for any inquiries about our egg tray machines and services.

Project Scope

Do you need a complete project solution or a partial solution? Our team can customize the perfect setup for your specific needs and budget constraints.

Product Expectations

What kind of finished product do you expect, and what quality standards are important to you?

Project Timeline

What is your expected timeline for project implementation and operation?

Budget Range

What is the approximate budget range for your project procurement?

Send Us Your Information

Accurate project information will help us provide the perfect solution for your needs.