Egg Tray Production Line – High Efficiency Pulp Molding Machines for Export

Engineered for stable quality, high efficiency, and export-ready pulp molded trays. Transform waste paper into durable egg trays with our system-level production solution.

A high-quality egg tray is not produced by a single machine, but by a well-engineered egg tray production line where every process step works together in harmony.

With over 30 years of experience in pulp molding engineering, our system-level approach ensures strong, uniform, and export-ready egg trays.

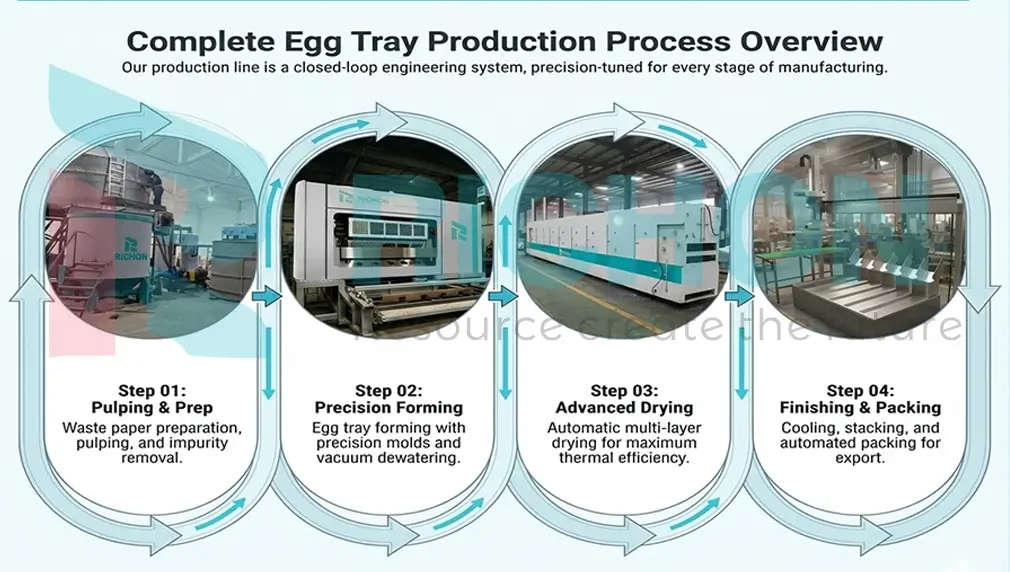

Complete Egg Tray Production Process Overview

Our production line is a closed-loop engineering system, precision-tuned for every stage of manufacturing.

Pulping & Prep

Waste paper preparation, pulping, and impurity removal.

Precision Forming

Egg tray forming with precision molds and vacuum dewatering.

Advanced Drying

Automatic multi-layer drying for maximum thermal efficiency.

Finishing & Packing

Cooling, stacking, and automated packing for export.

* Each stage is customized based on your raw materials, capacity requirements, and product standards.

Raw Material Adaptability

Different regions have different waste paper qualities. Our lines are engineered to handle a wide range of inputs while maintaining structural integrity.

Waste Corrugated (OCC)

Highest fiber strength for heavy-duty export trays.

Old Newspapers

Excellent for surface smoothness and easy pulping.

Mixed Waste Paper

Optimized pulping parameters to handle varied fiber lengths.

Pulp Boards / Bagasse

Eco-friendly virgin fibers for high-end food-grade packaging.

Learn how specific process adjustments can turn lower-grade paper into high-strength trays.

Read Process Details →Advanced Pulping System for Quality Control

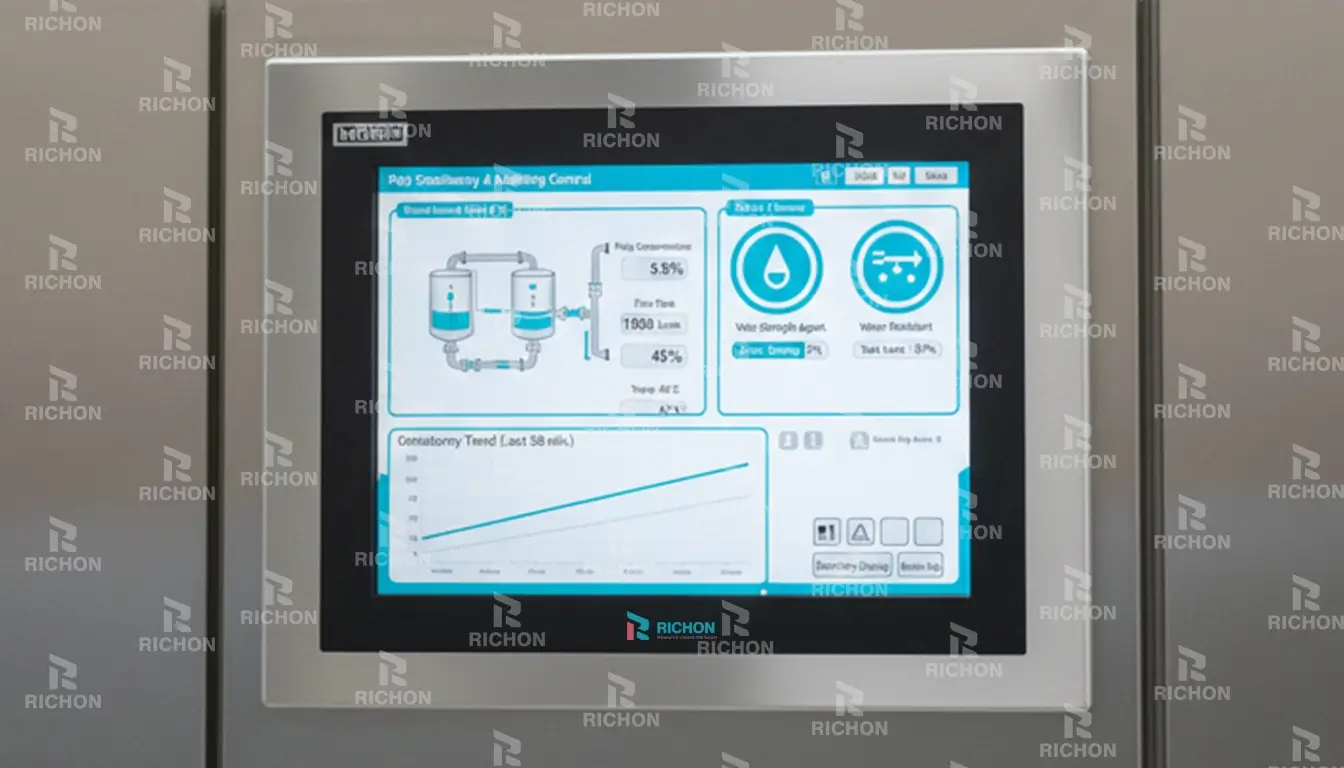

The pulping system is the foundation of stable egg tray quality. We focus on fiber integrity and consistency to ensure every tray meets export standards.

Consistency Control

Accurate pulp concentration automation ensures uniform fiber distribution and consistent tray weight.

Impurity Removal

Multi-stage screening protects precision molds and significantly reduces nozzle clogging during the forming stage.

Additive Compatibility

Integrated dosing systems support wet-strength agents and eco-friendly water-resistant coatings.

Unlike basic systems, our design prioritizes long-term process stability over short-term throughput numbers.

Precision Forming System & Egg Tray Mold Design

The forming section is where quality is solidified. Our systems control shape, thickness uniformity, and surface finish through integrated mechanical engineering.

Custom Forming Machines

Highly adaptable rotary or reciprocating systems matched perfectly to your specific output requirements and pulp characteristics.

High-Precision Molds

CNC-machined molds featuring a proprietary engineered mesh structure to facilitate rapid vacuum drainage and smooth demolding.

Dimensional Stability

Advanced wet-pressing and transfer technology ensures minimal deformation, maintaining tray integrity before entering the dryer.

Holistic Design: Our egg tray molds are developed as an integral part of the production line workflow—not as independent, third-party components.

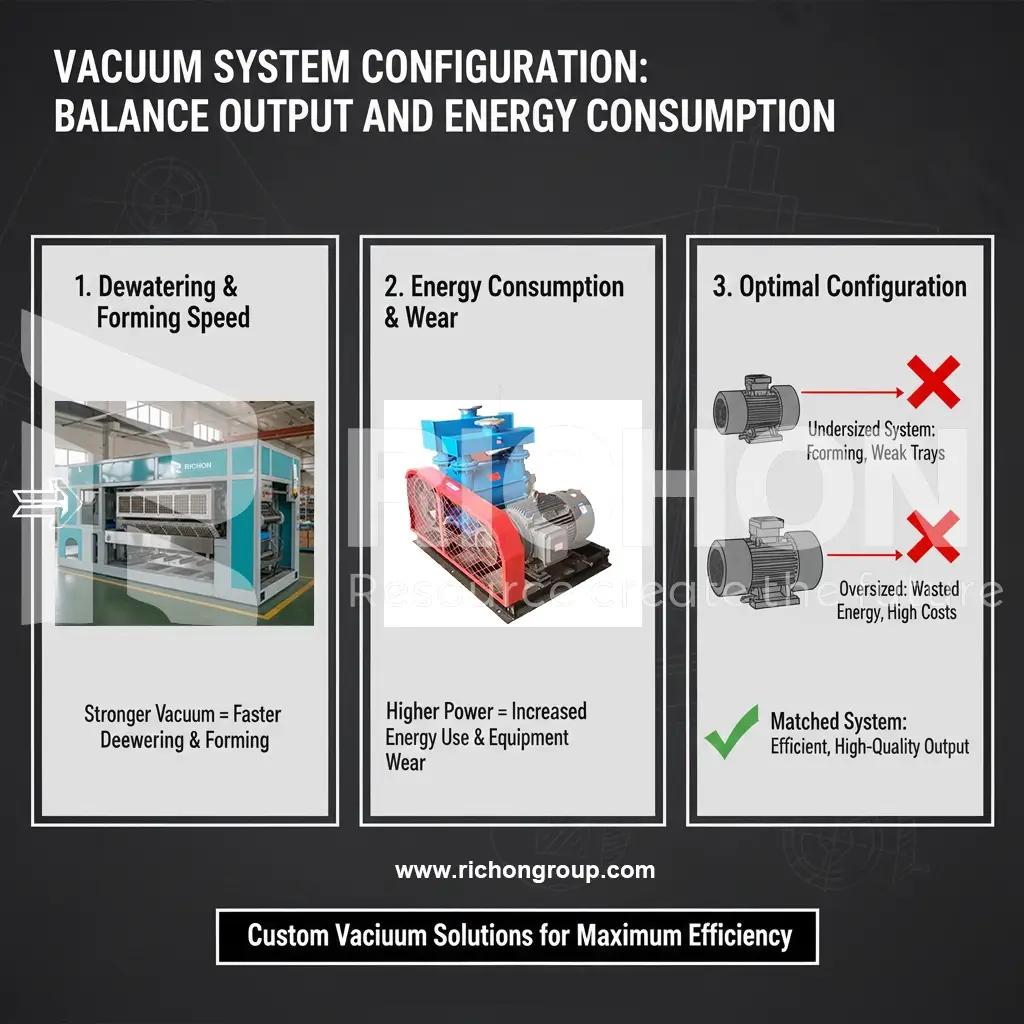

Optimized Vacuum System

The vacuum system is the engine of productivity, directly impacting forming speed, dewatering efficiency, and overall energy consumption.

Engineering Calculation: We calculate vacuum capacity based on your output target, mold quantity, and cycle time—eliminating underperformance and energy waste.

Market-Ready Applications

Our production lines are engineered to produce a diverse range of high-strength pulp packaging, meeting global standards for the poultry and logistics industries.

Chicken Egg Trays

Standard 30-cell and retail-ready designs.

Duck Egg Trays

Deep-pocket molds for larger, delicate eggs.

Transport & Storage

High-density trays for bulk warehouse stacking.

Export Packaging

Uniform quality for international shipping logistics.

Egg Tray Production Line Capacity & Automation

Complete production solutions including pulping, forming, drying, and stacking units. *Configurations may vary based on raw materials and factory conditions.

| Configuration | Capacity (pcs/h) | Power Range | Labor / Shift | Automation | Application |

|---|---|---|---|---|---|

| REM 4-1 – Starter Line | 1,000–1,500 | 34.9–46 kW | 3–4 persons | Semi-auto | Small farms, entry-level |

| REM 4-4 – Medium Scale | 2,500–3,000 | 58–88 kW | 3–5 persons | 60%–100% | Local production |

| REM 4-8 – Advanced | 4,000–4,500 | 127–144 kW | 3–5 persons | Fully Automatic | Growing operations |

| REM 5-8 – High Output | 5,000–5,500 | 153–190 kW | 3–5 persons | Fully Automatic | Export-oriented |

| REM 6-8 – Industrial | 6,000–6,500 | 226–239 kW | 3–5 persons | Fully Automatic | Large-scale factories |

| REM 8-8 – High-Speed | 8,000–9,000 | 360–375 kW | 3–5 persons | Fully Automatic | Mass production |

| REM 10-8 – Smart Line | 10,000–11,000 | 463–491 kW | 3–5 persons | Smart Automation | Industrial operations |

| Custom Solutions | Custom | Custom | Minimal | Fully Customized | Ultra-large projects |

Need detailed machine specifications and forming unit parameters?

View All Machine Models →Contact Us

Get in touch with our team for any inquiries about our egg tray machines and services.

Project Scope

Do you need a complete project solution or a partial solution? Our team can customize the perfect setup for your specific needs and budget constraints.

Product Expectations

What kind of finished product do you expect, and what quality standards are important to you?

Project Timeline

What is your expected timeline for project implementation and operation?

Budget Range

What is the approximate budget range for your project procurement?

Send Us Your Information

Accurate project information will help us provide the perfect solution for your needs.