Pulp Molding Industry Blog

Explore comprehensive guides, technical insights, project setup tutorials, and industry trends related to pulp molding machinery and egg tray production.

How-to Guide

How-to Guide

How to Start a Waste Paper Recycling Egg Tray Project

A complete guide for beginners covering everything you need to know about starting a waste paper recycling egg tray project. This comprehensive tutorial walks you through equipment selection, plant layout design, investment cost analysis, raw material requirements, and production workflow optimization. Learn how to transform waste paper into valuable egg trays with sustainable production methods that are both environmentally friendly and profitable.

Discover the key factors for success, including choosing the right machinery capacity, understanding drying system options, navigating regulatory requirements, and implementing quality control measures. Whether you’re an entrepreneur looking to enter the sustainable packaging industry or an existing business expanding your operations, this guide provides practical insights based on real-world experience.

Read Full Article How-to Guide

How-to Guide

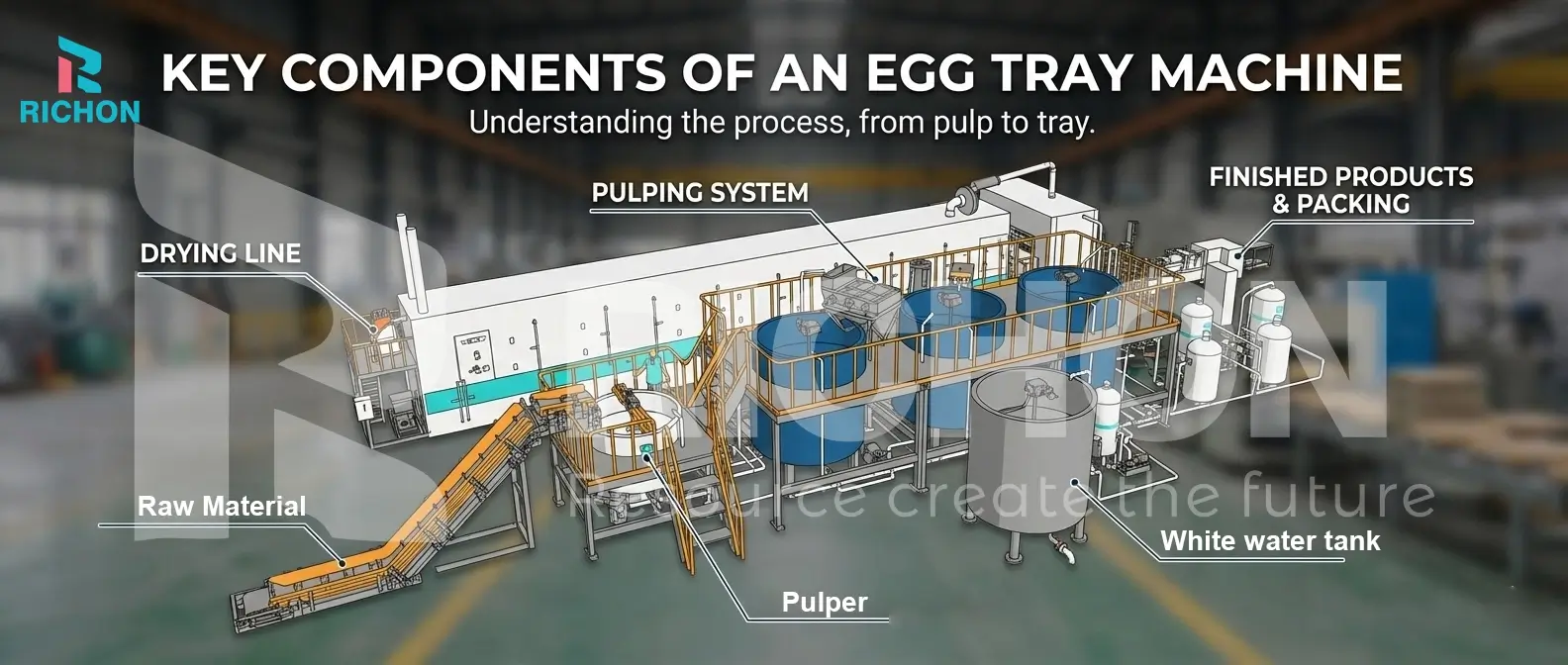

Key Components of an Egg Tray Machine: Mechanical, Electrical, and Pneumatic Systems

Egg tray machines rely on mechanical, electrical, and pneumatic components to efficiently transform waste paper into durable, high-quality egg trays. Understanding these key components ensures reliable performance, lower maintenance, and stable production output.

This guide covers mechanical parts such as linkage and gear transmissions, electrical systems including proximity switches and time relays, and pneumatic components that assist with mold clamping and dewatering. Following proper maintenance practices can significantly reduce downtime and improve overall efficiency.

Read Full Article Process Guide

Process Guide

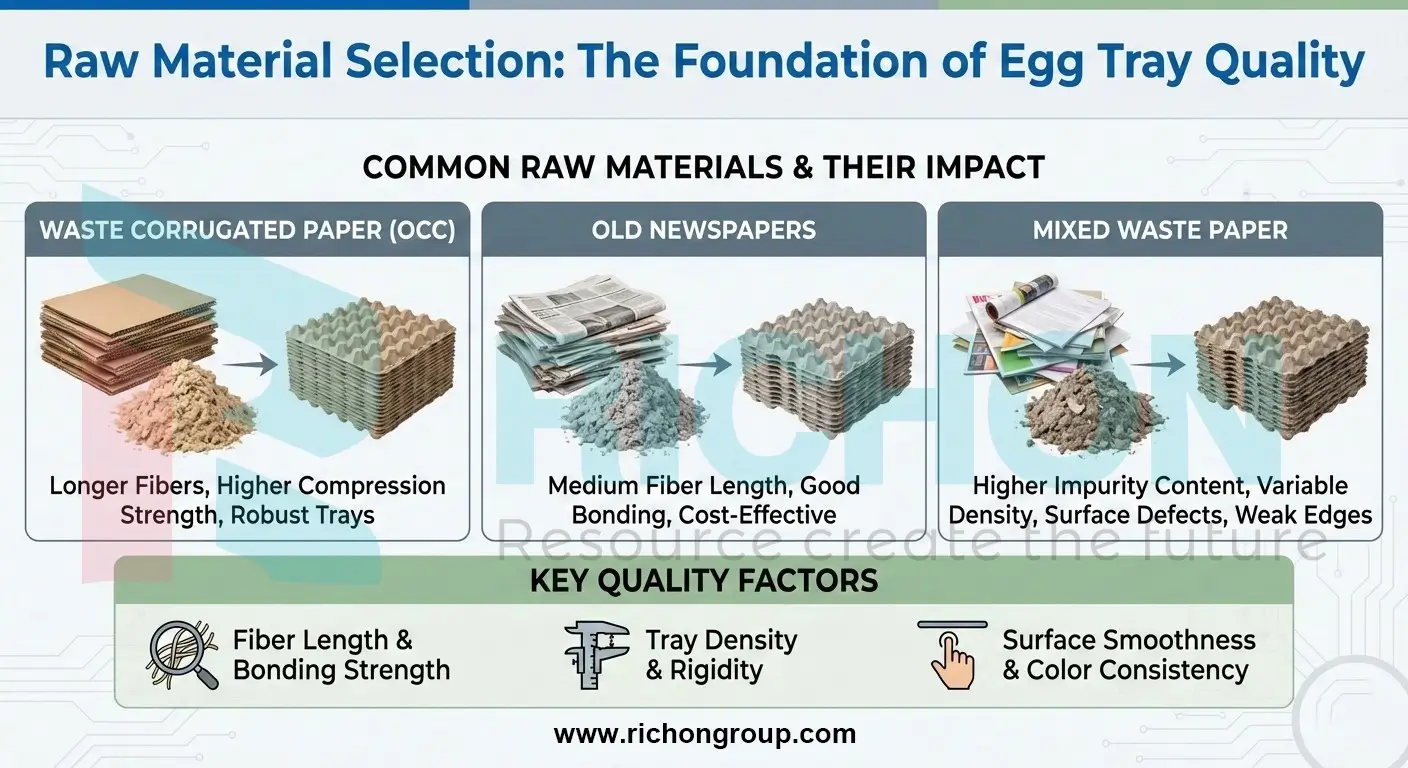

Egg Tray Machine Process Details That Affect Product Quality

Product quality in egg tray manufacturing is determined not only by machine structure, but more importantly by process control. Key variables such as pulp concentration, vacuum strength, forming time, pressing pressure, and drying temperature directly influence tray strength, surface finish, and dimensional consistency.

This article breaks down each critical process stage and explains how optimizing forming and drying parameters can significantly reduce defects, improve load-bearing capacity, and ensure stable long-term production.

Read Full Article Cost Insight

Cost Insight

What Determines the Real Production Cost of an Egg Tray Production Line?

The real production cost of an egg tray production line is determined by multiple factors beyond just the equipment price. Raw material availability, energy consumption, automation level, machine configuration, and long-term factory infrastructure all play a role in shaping the true cost per tray.

Understanding these variables helps global buyers make smarter investment decisions and ensures stable, high-quality egg tray production over time.

Read Full Article Price Insight

Price Insight

Egg Tray Making Machine Price: What Really Affects the Cost?

Egg tray making machine price varies widely depending on production capacity, automation level, mold design, drying system configuration, and raw material adaptability. Machines with similar output often differ significantly in real value.

This article explains how egg tray machine prices are formed, what truly drives cost differences, and how global buyers can evaluate equipment beyond the initial quotation.

Read Full ArticleMore Articles Coming Soon

We’re currently preparing more valuable content about pulp molding technology, industry trends, technical solutions, and case studies. Subscribe to be notified when new articles are published.

We respect your privacy. Unsubscribe at any time.