Pulp Molding Machines & Production Line Solutions

egg tray production lines, coffee tray production lines,Industrial Packaging Production Lines, apple tray production line,and custom pulp molding production lines.

Hey there! With thirty years in this industry, I can tell you straight – finding reliable pulp molding equipment can be challenging. That’s where we come in.

We’re your one-stop provider of high-efficiency pulp molding machinery. We supply complete production line solutions for egg trays, fruit trays, industrial packaging, and biodegradable tableware. Whether you need a 1,000 pcs/hr starter line or a massive 10,000+ pcs/hr fully automatic system, our machines deliver the stable performance, low energy consumption, and sustainable packaging benefits that’ll make your operation profitable and future-ready.

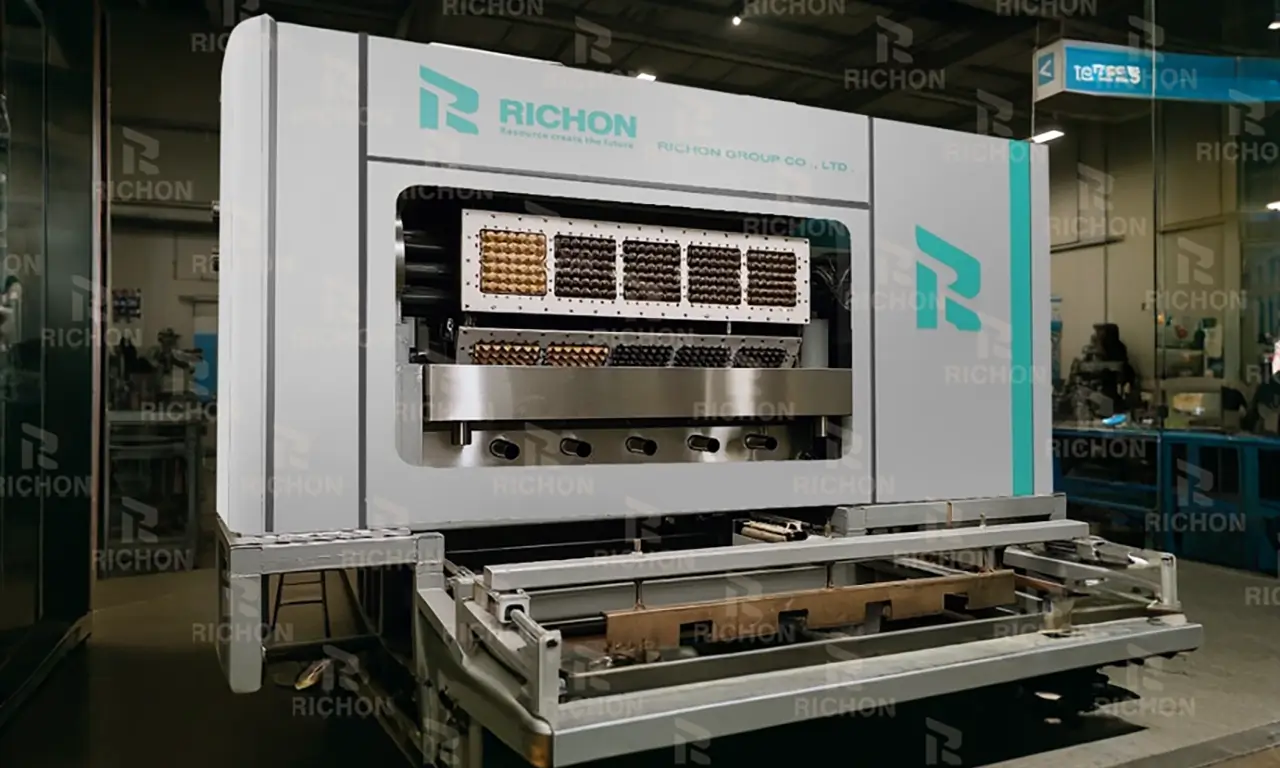

Fully automatic pulp molding production line with integrated drying system

Egg Tray Production Lines

Discover our range of high-quality pulp molding machines designed for efficiency, durability, and exceptional performance in egg tray manufacturing

Hey there! Having worked in this industry for over thirty years, I can tell you that not all egg tray machines are created equal. The right equipment makes all the difference in your bottom line.

We've designed these 6 models to cover every production scenario - from small poultry farms to industrial-scale operations. Each line is engineered with the same core principles: reliability, efficiency, and ease of operation. Let me walk you through what makes each model special.

Basic Starter

Perfect for small farms or businesses starting in egg tray production. Sime-automation, designed for ease of use and low initial investment.

- Capacity: 1,000-1,500 pcs/hr

- Power: 34.9-46 kW

- Workers needed: 3-4 p/shift

- Required area: 12x10 meters

- Drying: Natural drying

- Mold types: egg tray/egg box

Standard Semi-Auto

Our most popular model! Semi-automatic operation with partial automation for higher efficiency while maintaining affordability. Ideal for medium-sized operations.

- Capacity: 2,500-3,000 pcs/hr

- Power: 58-88 kW

- Workers needed: 3-5 p/shift

- Required area: 30x15x6 meters

- Automation: 60%-100%automated

- Drying: Natural drying/Metal drying

Advanced Auto

Fully automatic production with integrated drying system. Higher output with minimal labor requirements. Perfect for businesses looking to scale up production significantly.

- Capacity: 4,000-4,500 pcs/hr

- Power: 127-144 kW

- Workers needed: 3-5p/shift

- Footprint: 35x15x6 meters

- Automation: 100% automated

- Drying: Metal drying system

- Packing: Automatic stacking

Advanced Auto

Fully automatic pulp molding production line with integrated drying system. Advanced automation ensures superior stability and reliability, with production efficiency 20–30% higher than industry standards. Perfect for businesses aiming to scale up operations with minimal labor.

- Capacity: 5,000-5,500 pcs/hr

- Power: 153-190 kW

- Workers needed: 3-5 p/shift

- Footprint: 35x15x6 meters

- Automation: 100% automated

- Drying: Metal drying system

- Control: PLC system with touchscreen

Advanced Auto

The REM6-8 delivers high-capacity production at 6,000–6,500 pcs/h with a fully automatic system designed for scale. Equipped with PLC control, it ensures stable operation, precise forming, and consistent drying quality. Minimal labor is required, making it ideal for factories aiming to significantly expand output while maintaining efficiency and reliability.

- Capacity: 6,000-6,500 pcs/hr

- Power: 226-239 kW

- Workers needed: 3-5 p/shift

- Footprint: 35x15x6 meters

- Automation: 100% automated

- Drying: Metal drying system

- Control: PLC system with touchscreen

High-Speed Line

The REM 8-8 is our highest-capacity model, delivering 8,000–9,000 pcs/h with fully automatic operation and PLC control. It offers industry-leading stability and efficiency, ensuring fast forming, consistent drying quality, and minimal labor requirements. A perfect choice for factories looking to expand large-scale production with reliable, high-performance equipment.

- Capacity: 8,000-9,000 pcs/hr

- Power: 360-375 kW

- Workers needed: 3-5 p/shift

- Footprint: 40x20x6 meters

- Automation: 100% automated

- Drying: Metal drying system

- Control: PLC system with touchscreen

Premium System

An industry-leading system designed for large-scale industrial production. Featuring advanced automation and energy recovery, it delivers maximum output with minimal energy consumption. Production capacity is 16–21% higher than standard systems, ensuring stable 24/7 operation, low labor demand, and a clear competitive advantage.

- Capacity: 10,000-11,000 pcs/hr

- Power: 463-491 kW

- Workers needed: 3-5 p/shift

- Footprint: 45x25x6 meters

- Automation: Full smart automation

- Energy: Heat recovery system

- Monitoring: Remote IoT capability

Custom Line

A fully customized solution built for ultra-large-scale production. Engineered to meet the advanced requirements of industrial clients, with a modular design that supports seamless expansion and long-term scalability.

- Capacity: Custom pcs/hr

- Power: Custom configuration

- Automation: Complete automation

- Footprint: Custom layout

- Features: Custom drying & stacking

- Integration: Plant-wide system integration

Egg Tray Machine Comparison

| Model | Capacity (pcs/hr) | Power Consumption | Labor Required | Automation Level | Best For |

|---|---|---|---|---|---|

| REM 4-1 (Basic Starter) | 1,000-1,500 | 34.9-46 kW | 3-4 p/shift | Semi-auto | Small farms, startups |

| REM 4-4 | 2,500-3,000 | 58-88 kW | 3-5 p/shift | 60%-100% automated | Medium businesses |

| REM 4-8 (Advanced Auto) | 4,000-4,500 | 127-144 kW | 3-5 p/shift | 100% automated | Growing operations |

| REM 5-8 (Advanced Auto) | 5,000-5,500 | 153-190 kW | 3-5 p/shift | 100% automated | Growing operations |

| REM 6-8 (Advanced Auto) | 6,000-6,500 | 226-239 kW | 3-5 p/shift | 100% automated | Growing operations |

| REM 8-8 (High-Speed) | 8,000-9,000 | 360-375 kW | 3-5 p/shift | 100% automated | Large-scale production |

| REM 10-8 | 10,000-11,000 | 463-491 kW | 3-5 p/shift | Full smart automation | Industrial operations |

| REM-CUSTOM | Custom | Custom | Minimal | Complete automation | Ultra-large facilities |

Not Sure Which Model is Right for You?

With 30+ years in the industry, I've helped hundreds of clients find their perfect egg tray production solution. Let's discuss your specific needs and I'll recommend the best model for your operation.

Get Free ConsultationThese egg tray machines can be integrated into a complete egg tray production line solution.

Coffee Tray Production Lines

Specialized pulp molding solutions for coffee cup trays and carriers. Engineered for high-speed production of durable, eco-friendly coffee packaging.

Hey coffee professionals! If you're in the coffee business, you know that presentation matters almost as much as the brew itself. The right tray not only protects your cups but enhances your brand image.

With over thirty years of experience in pulp molding machinery, I've designed these three coffee tray lines to meet every scale of operation. Whether you're a local coffee shop looking to brand your own trays or a large distributor needing high-volume production, we've got you covered.

Each system is built with the coffee industry in mind - fast production cycles, food-safe materials, and designs that make your product stand out on the shelf.

Small-scale coffee tray production line

Perfect for small coffee shops and local roasters who want to produce their own branded trays. Semi-automatic operation with quick mold changes for different tray designs.

- Capacity: 1200-1500 trays/hour

- Power: 34.9-46 kW

- Workers needed: 3-4 p/shift

- Footprint: 12x10 meters

- Tray sizes: 2, 4cup holders

- Custom branding available

Commercial Production Line

Our best-selling model for medium to large coffee distributors. Fully automated with integrated drying and stacking. Perfect for businesses supplying multiple coffee shops or supermarkets.

- Capacity: 2,500-3,000 trays/hour

- Power: 58-88 kW

- Workers needed: 3-5 p/shift

- Footprint: 30x15x6 meters

- Automation: 60%-100% automated

- Drying: Natural drying/Metal drying

- Stacking: Automatic counting & stacking

- Multiple tray designs simultaneously

Industrial High-Speed Line

For large-scale coffee producers and packaging companies. Complete automation with PLC control, energy recovery, and minimal operator intervention. Designed for 24/7 operation.

- Capacity: 6,000-6,500 trays/hour

- Power: 226-239 kW

- Workers needed: 3-5 p/shift

- Footprint: 35x15x6 meters

- Automation: 100% automated

- Drying: Multi-stage tunnel dryer

- Control: PLC with touchscreen interface

- Energy: Heat recovery system

- Quality: Automated inspection system

Coffee Industry Specific

Designed specifically for coffee tray production with optimal cup holder spacing and durability.

Eco-Friendly Materials

Produce 100% biodegradable trays from recycled paper pulp, aligning with sustainable coffee culture.

Fast Production Cycles

Quick drying technology ensures rapid production cycles to meet high coffee industry demands.

Brand Customization

Easy mold changes for different tray designs and branding options to match your coffee shop aesthetic.

Coffee Tray Machine Comparison

| Model | Capacity (trays/hr) | Power Consumption | Labor Required | Automation Level | Best For |

|---|---|---|---|---|---|

| RCM-1500 (Compact Cafe) | 1500-1800 | 34.9-46 kW | 3-4 p/shift | Semi-automatic | Small cafes, local roasters |

| RCM-3000 (Commercial) | 2,500-3,000 | 58-88 kW | 3-5 p/shift | 60%-100% automated | Coffee distributors, chains |

| RCM-6000 (Industrial) | 6,000-6,500 | 226-239 kW | 3-5 p/shift | 100% automated | Large producers, packaging companies |

Coffee Shops & Cafes

Produce branded trays for your own locations

Coffee Roasters

Package your roasted beans with custom trays

Distributors

Supply multiple coffee businesses with trays

Packaging Companies

Offer coffee tray production as a service

Ready to Brew Your Own Coffee Trays?

Having worked with coffee businesses for over 30 years, I understand the unique needs of the coffee industry. Let's discuss how our coffee tray production lines can help you create eco-friendly, branded packaging that elevates your coffee experience.

Schedule a Free ConsultationIndustrial Packaging Production Lines

Specialized pulp molding solutions for protective packaging, edge guards, corner protectors, and industrial cushioning. Engineered for durability and product protection.

Hey industrial packaging professionals! Let me be straight with you - when it comes to protecting valuable products during shipping and handling, you can't afford compromises. The right protective packaging isn't just about preventing damage; it's about protecting your reputation and bottom line.

With over thirty years in the pulp molding machinery business, I've seen how the right equipment transforms packaging operations. These two industrial packaging lines are designed based on real-world manufacturing challenges - from protecting delicate electronics to safeguarding heavy machinery components.

Whether you're a packaging supplier serving multiple industries or a manufacturer needing in-house protective packaging, our machines deliver the precision, consistency, and reliability you need.

Semi-automatic Industrial Line

Perfect for medium-sized manufacturers and packaging suppliers. This versatile line produces a wide range of industrial protective packaging, including corner protectors, edge guards, and cushioning components. Semi-automatic operation with quick mold change capability.

- Capacity: Customized according to product specifications.

- Power: 55-85 kW

- Workers needed: 3-5 p/shift

- Footprint: 12x10 meters

- Mold change time: 1-2 hours

- Control system: PLC with basic interface

Fully automatic Industrial Line

Suitable for large-scale, highly automated industrial packaging manufacturers and mechanical parts suppliers. This high-performance production line can produce high-strength, exceptionally precise mechanical parts and protective packaging for industrial products. It is equipped with a comprehensive integrated quality control system to ensure stable and reliable automated production processes.

- Capacity: Customized according to product specifications.

- Power: 86-115 kW

- Workers needed: 3-5 p/shift

- Footprint: 30x15x6 meters

- Automation: 100% automated

- Drying: Multi-layer metal dryer

- Control system: Advanced PLC with touchscreen

- Quality control: Automated inspection system

Corner Protectors

Protect furniture, appliances, and machinery corners during shipping and handling

Edge Guards

Protect sharp edges of metal sheets, glass panels, and construction materials

Industrial Cushioning

Custom cushioning components for electronics, automotive parts, and machinery

Pallet Spacers

Interior packaging to separate and protect stacked products on pallets

Superior Protection

Our industrial packaging provides exceptional protection for high-value products, reducing damage rates and return costs significantly.

Custom Designs

Create custom packaging designs for specific products, ensuring perfect fit and maximum protection for unique shapes and sizes.

Sustainable Solution

Replace plastic foam and non-recyclable materials with 100% biodegradable paper pulp packaging that meets environmental regulations.

Industrial Packaging Machine Comparison

| Model | Capacity (pieces/hr) | Max Product Size | Automation Level | Power Consumption | Best Application |

|---|---|---|---|---|---|

| RIM-2 (Standard) | Customized according to product specifications. | Customized according to product specifications. | Semi-automatic | 55-85 kW | small and Medium manufacturers, packaging suppliers |

| RIM-MD1 (Heavy-Duty) | Customized according to product specifications. | Customized according to product specifications. | 100% automated | 86-115 kW | Large-scale production, heavy machinery packaging |

Electronics Manufacturing

Protect TVs, computers, and appliances during shipping

Furniture Industry

Corner and edge protection for furniture shipping

Automotive Parts

Cushioning for sensitive automotive components

Machinery & Equipment

Heavy-duty protection for industrial machinery

Need Industrial-Grade Protective Packaging Solutions?

With 10+ years of experience in industrial packaging machinery, I've helped businesses across industries reduce product damage and improve packaging efficiency. Whether you're protecting delicate electronics or heavy machinery, let's discuss how our industrial packaging lines can solve your specific challenges.

Schedule a Free ConsultationApple Tray Production Line

Commercial pulp molding solution designed for apple packing houses and fruit distributors.

After more than thirty years working with fruit packaging projects, one thing is clear: consistency and protection matter more than anything else.

This production line is built for commercial apple packing operations that need reliable output, stable tray quality, and efficient handling during storage and transport.

Commercial fruit tray packaging production line

This is our best-selling apple tray production line for commercial packaging plants. The fully automated system integrates forming, drying, and stacking into one smooth process, delivering stable output and highly uniform tray quality for orchards, supermarkets, packaging companies, and export operations. Thanks to a newly engineered hot-air drying duct design, this line achieves 11–14% higher overall energy efficiency compared with conventional systems, significantly reducing operating costs. Full automation also cuts labor requirements by 1–2 operators on average, improving productivity and process stability. Multiple tray sizes and specifications can be customized, allowing one production line to flexibly serve different packaging needs without sacrificing efficiency or quality.

- Capacity: 2,500–3,000 trays/hour

- Power consumption: 226-239 kW

- Labor required: 3-5 p/shift

- Fully-automatic forming system

- Metal drying & automatic stacking

- Enhanced ventilation tray design

- Multiple apple size configurations

Upgrade Your Apple Packaging Operation

If you're supplying supermarkets or export markets, consistent tray quality makes a real difference. Let's discuss how this line fits your packing capacity and fruit varieties.

Schedule a Free ConsultationContact Us

Get in touch with our team for any inquiries about our egg tray machines and services.

Project Scope

Do you need a complete project solution or a partial solution? Our team can customize the perfect setup for your specific needs and budget constraints.

Product Expectations

What kind of finished product do you expect, and what quality standards are important to you?

Project Timeline

What is your expected timeline for project implementation and operation?

Budget Range

What is the approximate budget range for your project procurement?

Send Us Your Information

Accurate project information will help us provide the perfect solution for your needs.