Who We Are

Leading the Future of Sustainable Packaging Technology

Founded in 2000, Richon Group is a leading global provider of **eco-friendly pulp molding and packaging equipment**. We specialize in delivering high-quality, efficient, and sustainable production solutions for **egg trays, food trays, fruit trays**, and other diverse paper-based products.

Our core mission is to seamlessly combine **innovation with environmental responsibility**, empowering businesses worldwide to transition towards smarter and **greener manufacturing** processes using waste paper resources.

We offer complete **turnkey project solutions**, encompassing everything from plant design and equipment installation to operational training and lifetime technical support.

Eco-Friendly Solutions

Pioneering green technology to convert waste paper into 100% biodegradable packaging products.

High-Efficiency Equipment

Delivering automated, stable, and low-consumption pulp molding machinery for maximum output.

Global Turnkey Projects

Providing full project support, from factory layout design to on-site installation and commission.

Lifetime Technical Support

Offering dedicated expertise and rapid remote assistance to ensure stable, long-term operation.

Our Vision & Mission

Vision

To become a global leader in environmentally friendly pulp molding and packaging equipment, driving the shift towards sustainable manufacturing.

Mission

To provide innovative, reliable, and high-efficiency solutions that enable our customers to achieve cost-effective and sustainable production worldwide.

Core Values

Quality First

Sustainability

Innovation

Customer Focus

Business

Our Meeting

Modern office spaces support the management of waste paper recycling egg tray projects. Teams can efficiently plan production lines, monitor raw material quality, and analyze investment returns, ensuring the project moves smoothly from concept to execution.

Our Core Expertise

We focus on developing advanced pulp molding and packaging machinery that stands out in precision, efficiency, and sustainability. Our robust engineering ensures reliable and cost-effective manufacturing for our clients.

Precision Engineering & Automation

Specializing in smart servo-controlled systems and high-precision molds to achieve superior product quality and consistency with minimal waste.

Sustainable Resource Utilization

Our machines are specifically designed to efficiently process **recycled raw materials** (waste paper, cardboard), maximizing sustainability and optimizing production costs.

Efficiency & Energy Optimization

Developing equipment with optimized pulp flow and energy-saving drying technology to enhance output while significantly minimizing environmental impact.

**Innovative Design & Robust Engineering:** A perfect blend of cutting-edge technology and durable components ensures long machine lifespan and consistent, high-volume production.

Diagram of Machine Innovation or Technology Showcase PlaceholderQuality & Compliance

Our products are certified by global authorities to ensure safety and excellence.

CE Certification

Compliance with European Union health, safety, and environmental protection standards.

EU Standard

QC Certificate

Certified ISO 9001:2015 Quality Management Systems for consistent manufacturing.

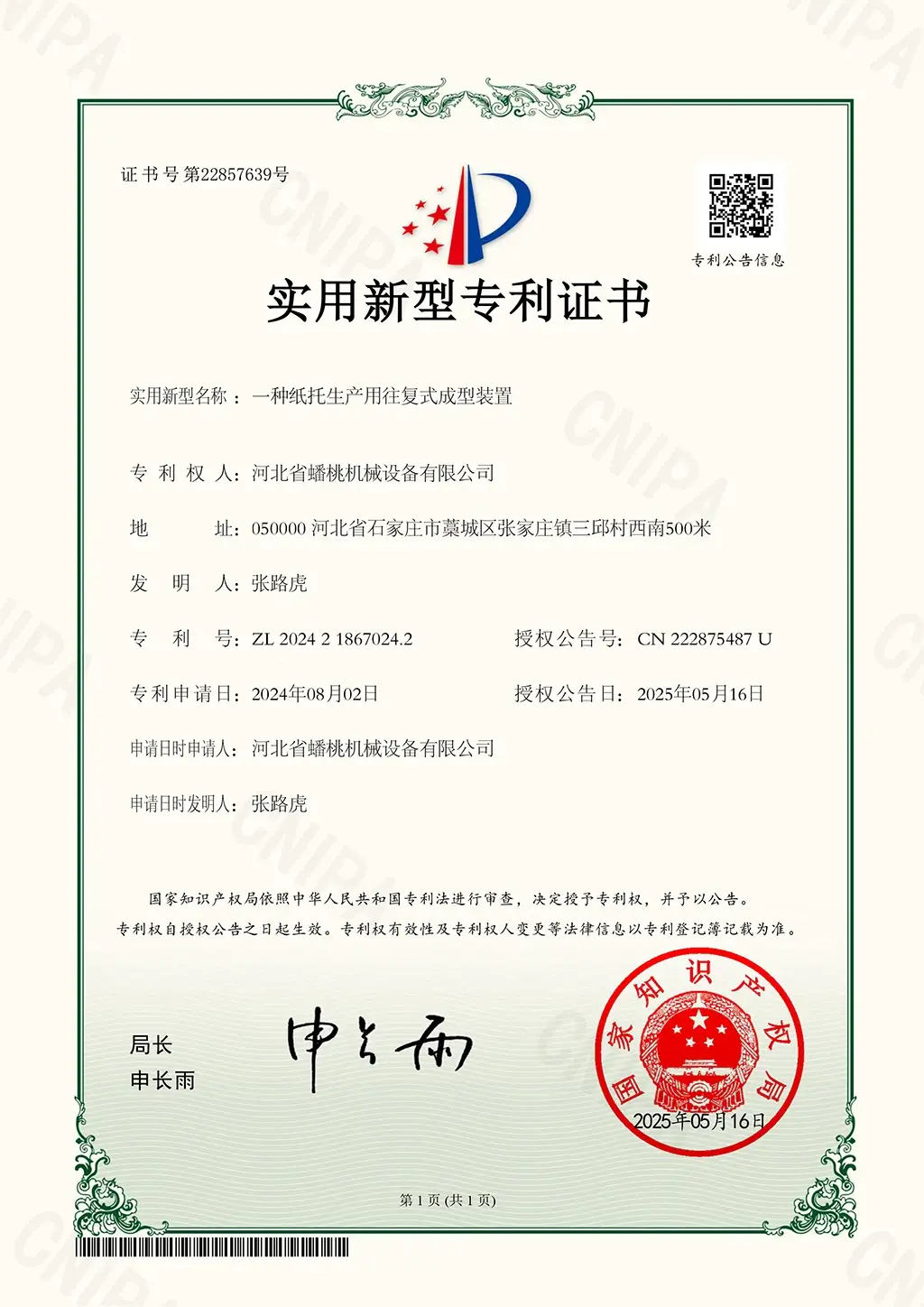

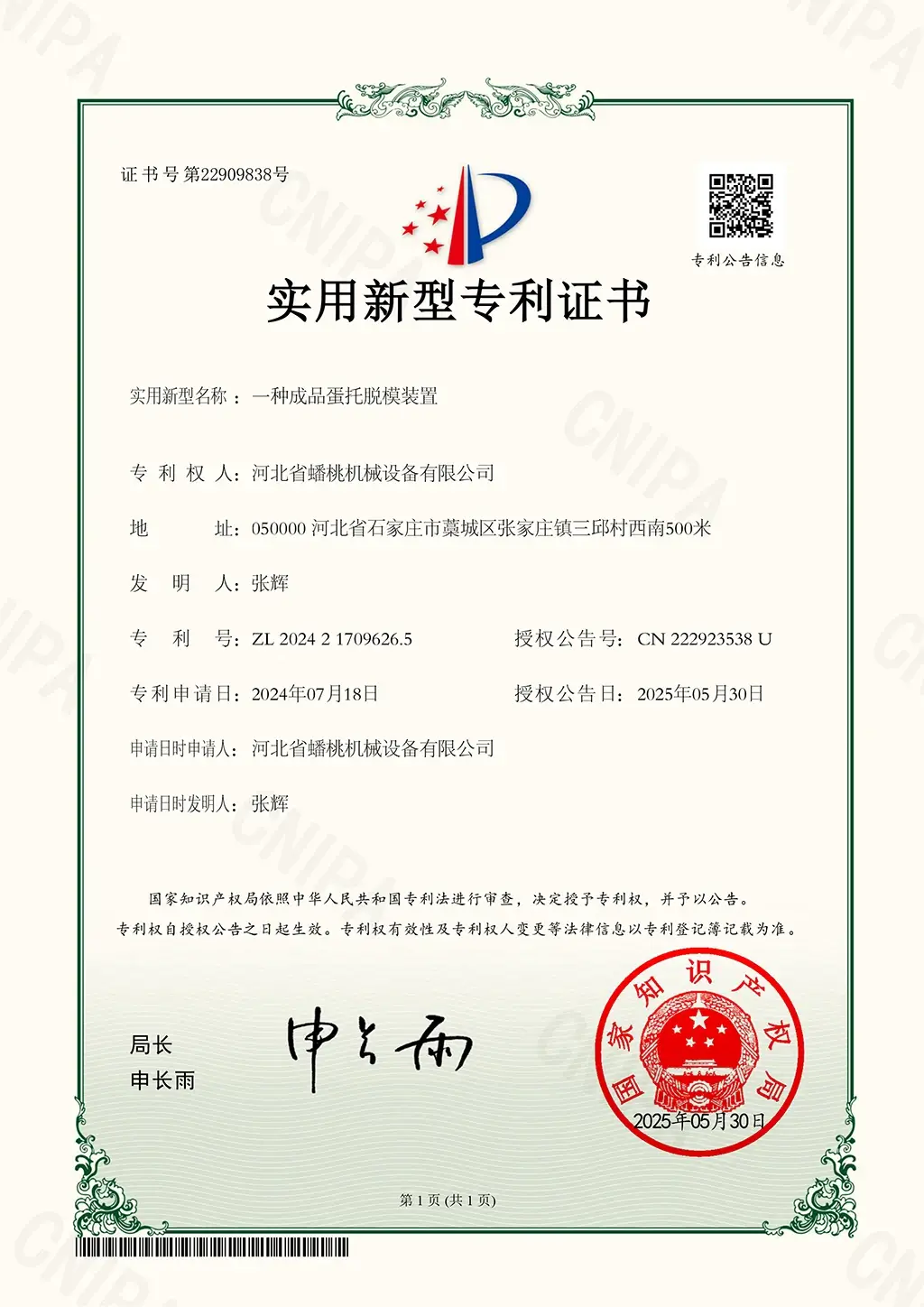

Quality AssuredIntellectual Property

Driven by innovation, protected by world-class technology patents.

Utility Model Patent

The reciprocating molding device for producing new types of paper pallets significantly improves process efficiency.

Utility Model Patent

A new type of device for demolding finished egg trays. It offers improved demolding and shaping performance with less deformation.

Design Patent

Ergonomic industrial casing design with integrated molding.

Contact Us

Get in touch with our team for any inquiries about our egg tray machines and services.

Project Scope

Do you need a complete project solution or a partial solution? Our team can customize the perfect setup for your specific needs and budget constraints.

Product Expectations

What kind of finished product do you expect, and what quality standards are important to you?

Project Timeline

What is your expected timeline for project implementation and operation?

Budget Range

What is the approximate budget range for your project procurement?

Send Us Your Information

Accurate project information will help us provide the perfect solution for your needs.