Egg Tray Molds Engineered from 30 Years of Pulp Molding Production Experience

In industrial egg tray manufacturing, molds are not interchangeable accessories. They are precision forming tools that directly define tray strength, dimensional stability, fiber efficiency, and long-term production cost. Our egg tray molds are designed based on real factory operation data accumulated over three decades of pulp molding engineering.

What Defines a High-Quality Egg Tray Mold in Industrial Production

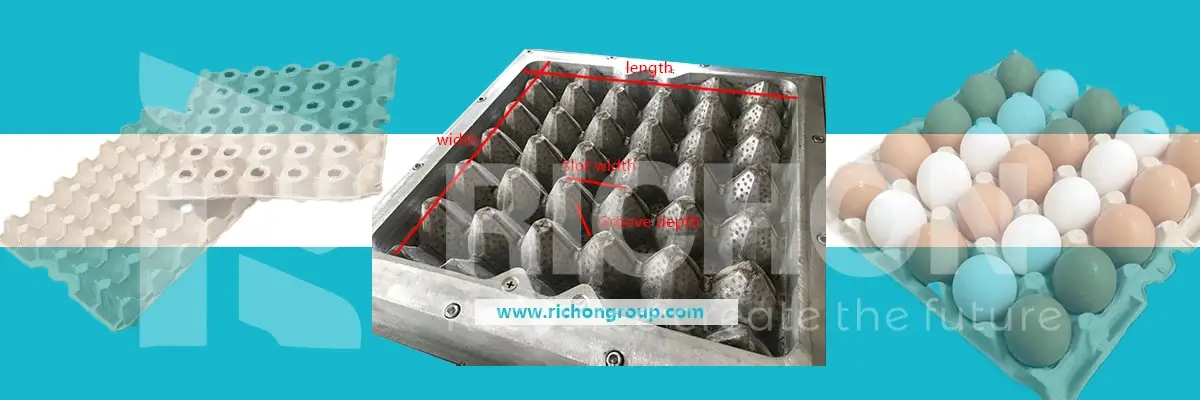

A high-quality egg tray mold controls how pulp fibers are distributed, how water drains during vacuum forming, and how stable the tray remains during transfer and drying.

From long-term factory observation, poor mold design typically leads to: uneven wall thickness, weak egg pockets, frequent deformation, excessive fiber consumption, and unstable production efficiency.

These issues do not appear immediately — they accumulate over months of operation, increasing energy, labor, and raw material costs.

Egg Tray Mold Manufacturer Focused on Finished Product Quality.

As a pulp molding equipment manufacturer with over 30 years of experience, we design our egg tray molds based on the requirements of continuous production, not short-term trials. Our mold designs aim to ensure molding precision and structural stability during long-term operation, according to customer egg tray mold requirements.

We strictly control and design our molds according to sample dimensions to ensure that the final paper egg trays meet the customer’s size and structural requirements.

Pulp Molding Molds and Materials for Egg Tray Production

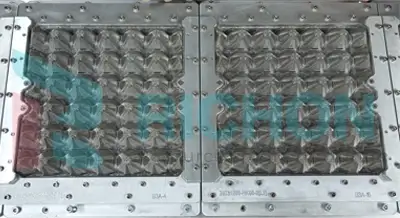

Aluminum Egg Tray Molds

Stable forming accuracy for automatic egg tray machines.

Plastic Egg Tray Molds

Cost-effective solution for semi-automatic production lines.

Reinforced Mold Frames

Designed for long-term high-vacuum forming cycles.

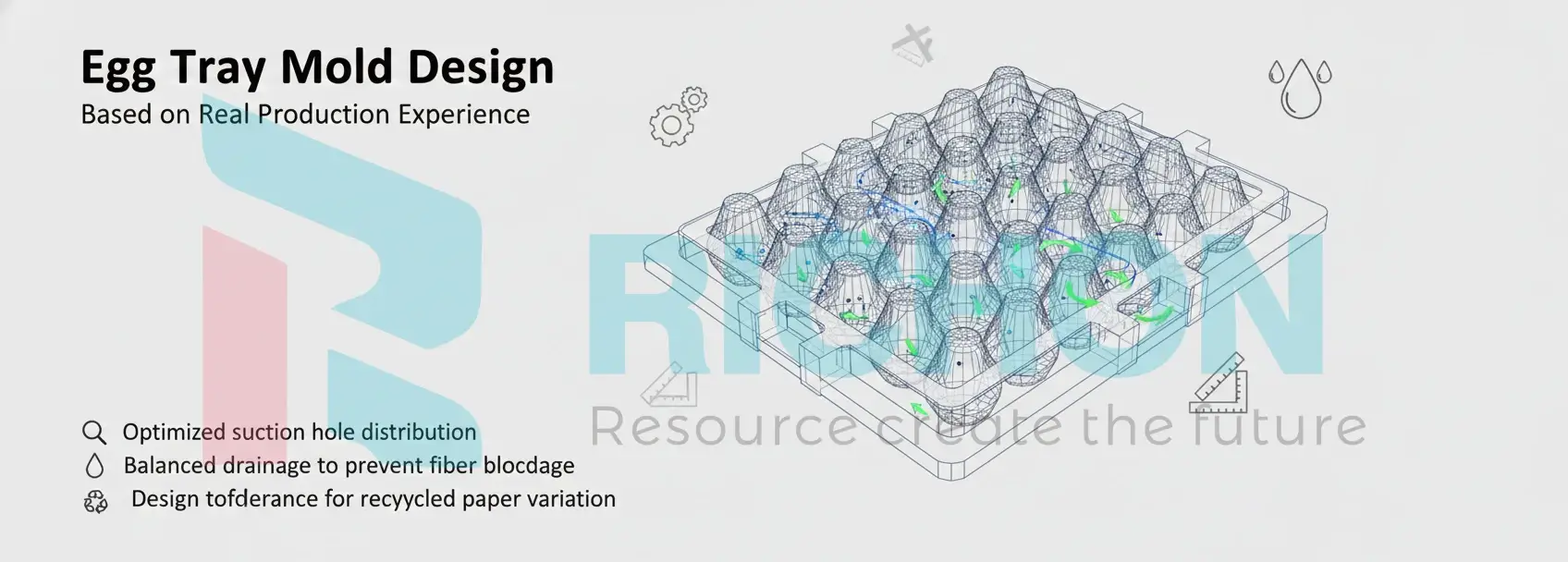

Egg Tray Mold Design Based on Real Production Experience

- Optimized suction hole distribution

- Balanced drainage to prevent fiber blockage

- Stable draft angles for smooth demolding

- Design tolerance for recycled paper variation

Egg Tray Molds for Automatic and Semi-Automatic Egg Tray Machines

- Compatible with rotary and reciprocating forming machines

- Production capacity from 1,000 to 12,000 pcs/hour

- Designed for recycled paper pulp systems

Discuss Your Egg Tray Mold Requirements with Our Engineers

Our engineers will recommend the most suitable egg tray mold solution based on your raw materials, capacity, and automation level.

Contact Our Engineering TeamContact Us

Get in touch with our team for any inquiries about our egg tray machines and services.

Project Scope

Do you need a complete project solution or a partial solution? Our team can customize the perfect setup for your specific needs and budget constraints.

Product Expectations

What kind of finished product do you expect, and what quality standards are important to you?

Project Timeline

What is your expected timeline for project implementation and operation?

Budget Range

What is the approximate budget range for your project procurement?

Send Us Your Information

Accurate project information will help us provide the perfect solution for your needs.