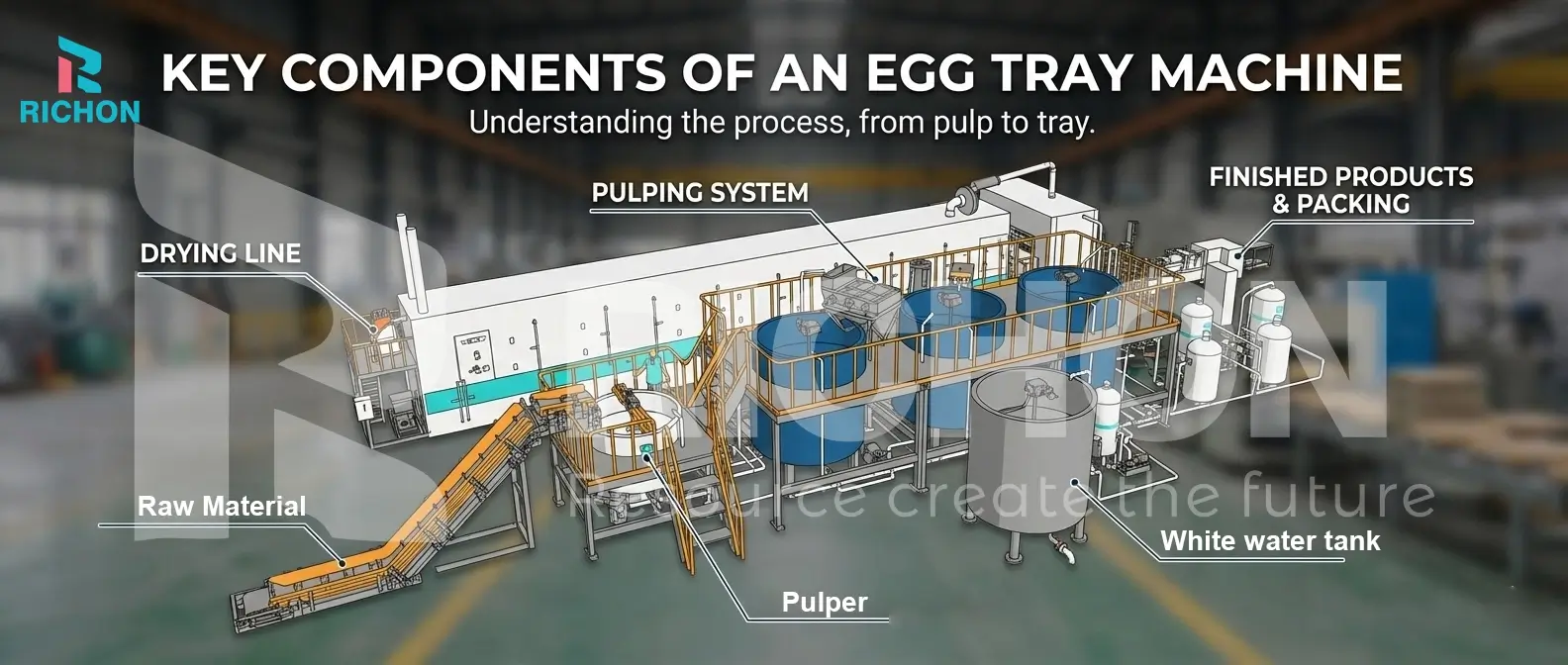

Key Components of an Egg Tray Machine

Egg tray machines play a crucial role in pulp molding production. Understanding the components of an egg tray machine helps manufacturers optimize performance and reduce downtime. Each part, whether mechanical, electrical, or pneumatic, contributes to the overall efficiency of the production line.

Egg tray machines may come in different models and configurations, but their core working principles and structural components remain largely consistent. Each part of the system plays a crucial role in forming, transferring, dehydrating, and drying pulp products. Understanding how these components work—and how they affect performance and maintenance—helps manufacturers choose reliable equipment and keep production running smoothly.

In general, egg tray machines are built from three major systems: mechanical, electrical, and pneumatic. Let’s take a closer look at how each part functions.

1.Mechanical Components of an Egg Tray Machine

The mechanical system forms the backbone of an egg tray machine. It includes linkage transmission, crankshaft transmission, groove wheel transmission, chain transmission, and gear transmission. Proper maintenance of these mechanical parts of the egg tray machine ensures smooth mold transfer and reliable production.

Common Mechanical Transmission Methods

Different machine types use various transmission methods, such as:

- Linkage transmission

- Crankshaft transmission

- Groove wheel transmission

- Chain transmission

- Gear transmission

These systems drive the forming molds, transfer molds, and rotary movements. Mechanical structures are straightforward, easy to inspect, and simple to repair—making them essential for maintaining stable production with minimal downtime.

Mechanical Track Structures

Egg tray machines may use different types of rail systems:

- Angle-iron sliding rails

- Single-arm bearing rails

- Rod-type sliding tracks

Rails guide the motion of molds. Common types include angle-iron sliding rails, single-arm bearing rails, and rod-type sliding tracks. These mechanical parts of an egg tray machine make troubleshooting easy and maintenance simple.

2.Electrical Systems in Egg Tray Machines

The electrical system is divided into two main parts:

A. Motor Control Circuit

This part is relatively simple when only basic start–stop functions are needed.

However, machines equipped with intermediate stops rely on:

- 1–2 proximity switches

- Time relays

- Motor control relays

The electrical system controls motor operation and timing. Simple machines may only need basic start–stop circuits. Machines with intermediate stops use proximity switches and time relays to ensure precise motor control. Proper handling of the electrical system for egg tray machine reduces failure rates.

B. Electrical Control for Pneumatic Components

When a machine uses air cylinders and solenoid valves, the logic becomes more complex:

- Each solenoid valve is triggered by a proximity switch

- Cylinders are controlled by switches → then by solenoid valves → then by mechanical actions

- The cylinder motion controls the dewatering valve

- These processes form a 4-step interconnected chain

If one component malfunctions, the chain reaction can stop the entire system.

3.Pneumatic System in Egg Tray Machines

To reduce breakdowns and make maintenance easier, many manufacturers prefer:

- More mechanical structure

- Fewer electrical components

- Minimal use of pneumatic parts

- Straightforward motion logic

A simpler design means:

- Lower failure rate

- Fewer interlocking dependencies

- Faster troubleshooting

- Lower maintenance costs

Air cylinders and solenoid valves help with mold clamping, lifting, and dewatering. A well-designed pneumatic system in an egg tray machine ensures smooth operations, though excessive pneumatic components can increase maintenance complexity.

Why Simpler Egg Tray Machines Are More Reliable

Reducing the number of electrical and pneumatic components while emphasizing mechanical parts of an egg tray machine leads to:

- Lower failure rates

- Faster troubleshooting

- Easier maintenance

Following this egg tray machine maintenance guide ensures continuous production and high operational efficiency.

Conclusion

Air cylinders and solenoid valves help complete certain auxiliary actions, such as:

- Mold clamping

- Mold lifting

- Dehydration valve opening

- Air pressure-assisted forming

Egg tray machines rely on mechanical, electrical, and pneumatic components to form, transfer, and dehydrate pulp trays. Optimizing the design for simplicity and proper maintenance reduces downtime and improves overall efficiency. Using this guide, manufacturers can better understand egg tray machine components and ensure reliable production.

Contact Us

Get in touch with our team for any inquiries about our egg tray machines and services.

Project Scope

Do you need a complete project solution or a partial solution? Our team can customize the perfect setup for your specific needs and budget constraints.

Product Expectations

What kind of finished product do you expect, and what quality standards are important to you?

Project Timeline

What is your expected timeline for project implementation and operation?

Budget Range

What is the approximate budget range for your project procurement?

Send Us Your Information

Accurate project information will help us provide the perfect solution for your needs.