Key Egg Tray Machine Process Details That Affect Product Quality

Introduction: Egg Tray Quality Is Determined by Process, Not Just Equipment

Most egg tray quality problems are caused by improper process design and control, not by the machine itself. A well-engineered egg tray production line integrates raw material selection, pulping, forming, drying, and mold design into one optimized system.

In modern egg tray manufacturing, many buyers focus mainly on machine models and output capacity, while overlooking the real factors that determine egg tray quality control.

From more than 30 years of engineering experience in the pulp molding industry, I can confidently state:

Most egg tray quality problems are caused by improper process design and control, not by the egg tray machine itself.

This article explains the key egg tray machine process details that directly affect strength, shape, surface quality, and consistency of egg trays, based on real industrial production experience.

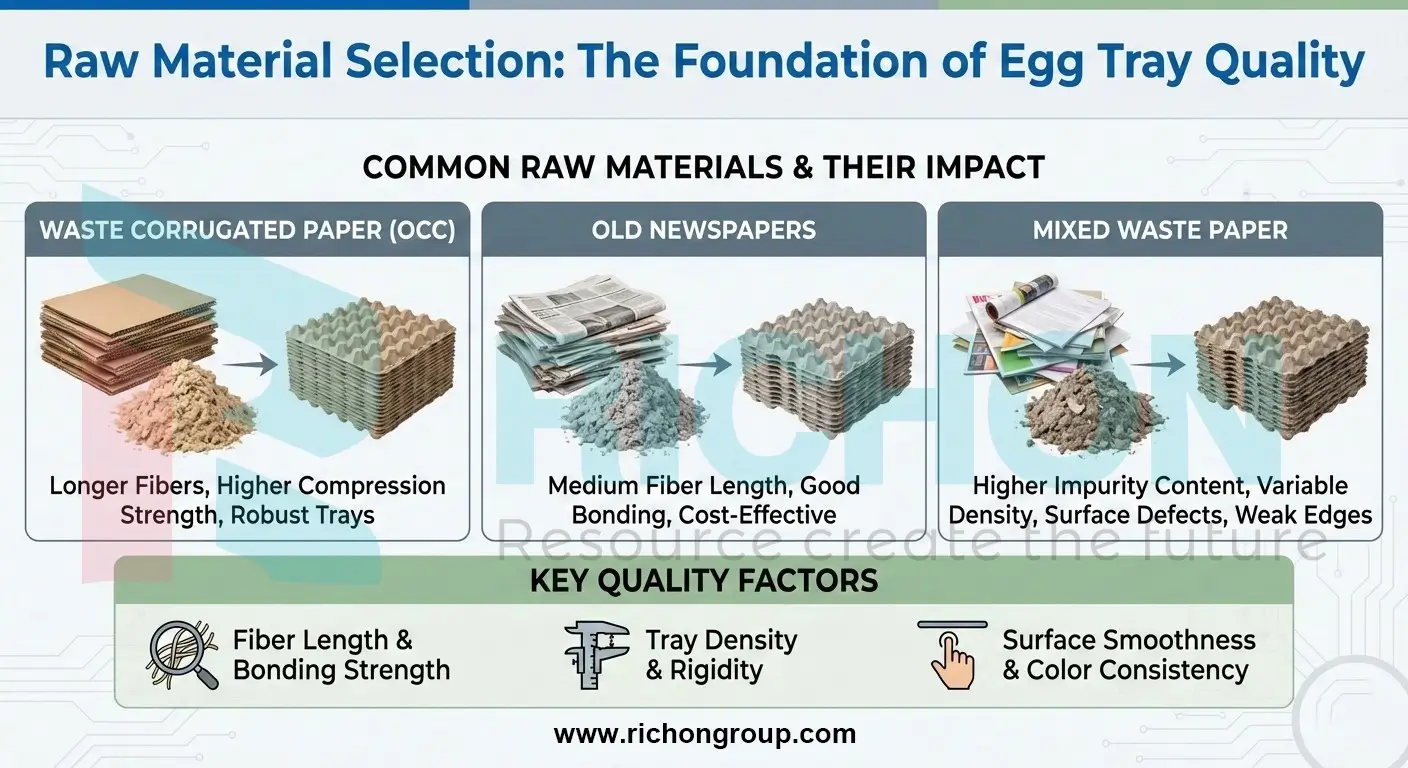

1.Raw Material Selection: The Foundation of Egg Tray Quality

Raw material selection is the first and most fundamental factor affecting egg tray quality.

Common raw materials include:

- Waste corrugated paper (OCC)

- Old newspapers

- Mixed waste paper

- Pulp boards or bagasse pulp (in some regions)

Different materials affect:

- Fiber length and bonding strength

- Tray density and rigidity

- Surface smoothness and color consistency

For example:

- Longer fibers improve compression strength

- High impurity content leads to weak edges and surface defects

Engineering insight:

There is no “best” raw material—only the most suitable combination based on product requirements and local waste paper conditions.

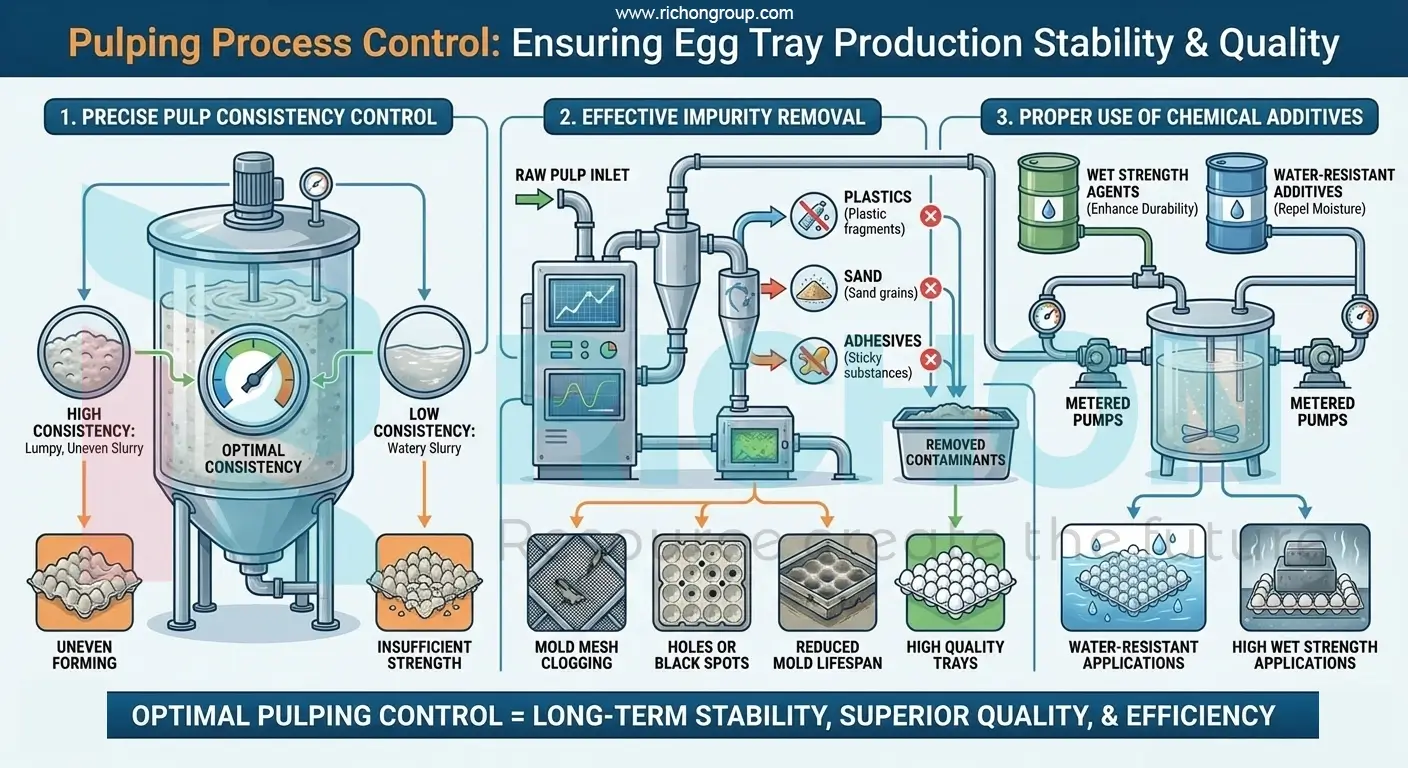

2.Pulping Process Control: Pulp Ratio and Impurity Removal

The pulping system plays a critical role in long-term production stability.

Key control points include:

• Precise pulp consistency control

- High consistency → uneven forming

- Low consistency → insufficient strength

• Effective impurity removal

Poor removal of plastics, sand, or adhesives can cause:

- Mold mesh clogging

- Holes or black spots on trays

- Reduced mold lifespan

• Proper use of chemical additives

Depending on application requirements:

- Wet strength agents

- Water-resistant additives

Engineering insight:

Chemical additives must be carefully matched with pulp composition and forming parameters, not blindly increased.

3.Forming Process: Matching Mold Mesh with Pulp Parameters

The forming stage determines egg tray shape, thickness uniformity, and surface quality.

A professional egg tray production line is never “one-size-fits-all”. It requires matching:

- Pulp raw material ratios

- Pulp concentration

- Mold structure

- Forming mesh specifications

Examples:

- Heavy-duty egg trays require higher drainage efficiency

- Export-grade trays demand finer mesh for smoother surfaces

Engineering insight:

Mold mesh design must serve the final product requirement, not standard configuration.

Effective egg tray mold design must be developed together with pulp parameters, rather than treated as a separate component. This is why a professional egg tray production line focuses on process matching instead of standard configurations.

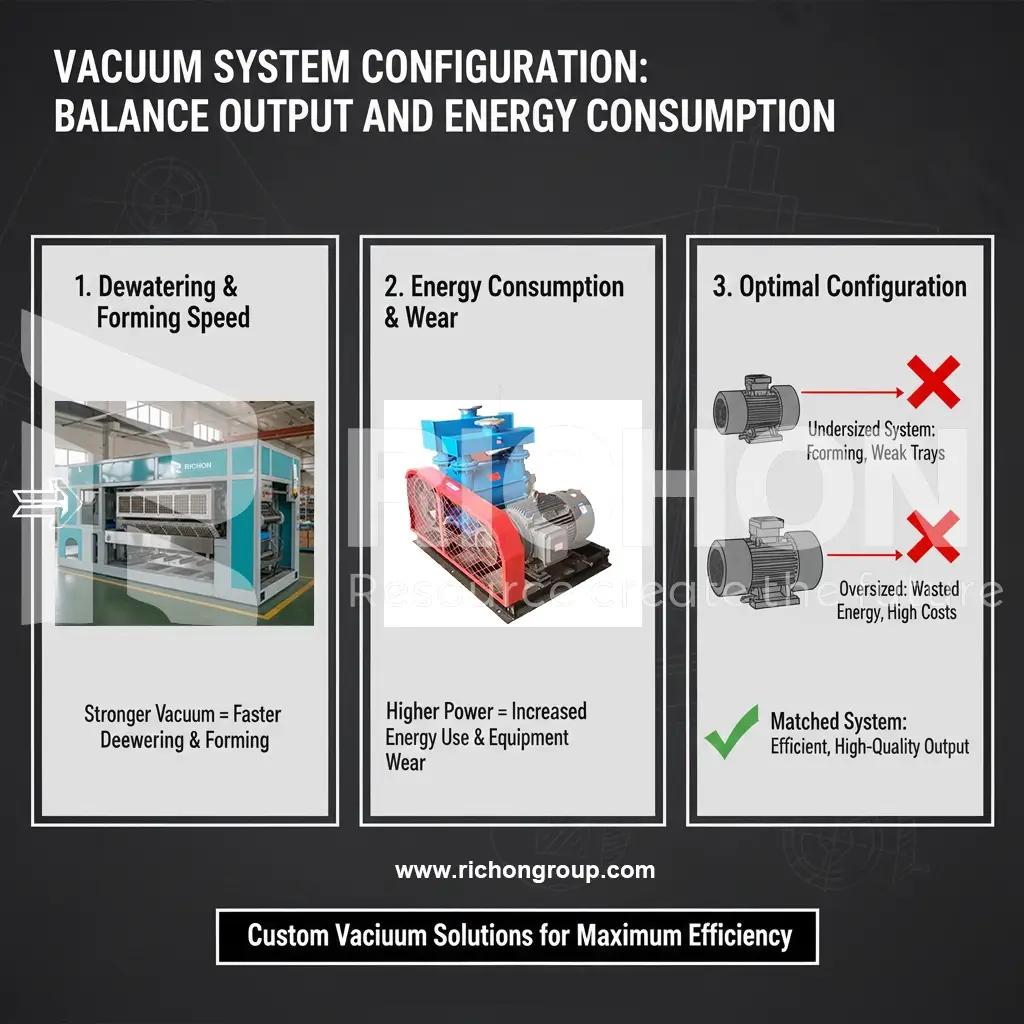

4.Vacuum System Configuration: Balance Output and Energy Consumption

The vacuum system directly affects:

- Forming speed

- Dewatering efficiency

- Overall energy consumption

A common misconception:

“Higher vacuum power means better production.”

In reality:

- Undersized systems cause incomplete forming

- Oversized systems waste energy and increase wear

Engineering insight:

Vacuum systems must be precisely matched to production capacity, mold quantity, and cycle time to achieve optimal efficiency.

5.Automatic Drying System: Custom Multi-Layer Design

Drying quality strongly influences final tray dimensions and appearance.

Modern egg tray lines typically use:

- Fully automatic multi-layer drying systems

- Common configurations: 6-layer or 8-layer structures

Layer selection depends on:

- Target output

- Plant layout

- Automation level

- Energy source (gas, biomass, steam, electric)

Engineering insight:

There is no universal drying solution—each system must be engineered for the customer’s site conditions.

6.Mold Design: Controlling Wet Tray Deformation

Many deformation problems originate before drying, during mold design.

Critical factors include:

- Structural support of wet trays

- Stress distribution during demolding

- Dimensional stability before entering the dryer

If wet tray deformation is excessive:

- Drying amplifies distortion

- Size consistency decreases

- Stacking stability is affected

Engineering insight:

A high-quality egg tray mold must prioritize wet-state stability, not just dry dimensions.

Conclusion: Egg Tray Quality Is a System Engineering Result

High-quality egg trays are never achieved by optimizing a single parameter. They result from:

Raw materials + pulping + forming + vacuum + drying + mold design

All six systems must be engineered and coordinated together.

If you are planning a new egg tray production line or upgrading an existing one, focusing on overall process engineering will deliver far better results than isolated adjustments.

If you are planning a new project or upgrading an existing factory, choosing a professionally engineered egg tray production line is the most effective way to ensure stable quality, energy efficiency, and long-term production reliability.

Contact Us

Get in touch with our team for any inquiries about our egg tray machines and services.

Project Scope

Do you need a complete project solution or a partial solution? Our team can customize the perfect setup for your specific needs and budget constraints.

Product Expectations

What kind of finished product do you expect, and what quality standards are important to you?

Project Timeline

What is your expected timeline for project implementation and operation?

Budget Range

What is the approximate budget range for your project procurement?

Send Us Your Information

Accurate project information will help us provide the perfect solution for your needs.