What Determines the Real Production Cost of an Egg Tray Production Line?

Many buyers searching for an egg tray production line cost or comparing an egg tray machine price expect a fixed number. In reality, the true production cost goes far beyond the initial machine quotation.

For international investors and factory owners, the real cost of an egg tray production line is determined by raw materials, energy structure, automation level, product standards, and long-term operating stability—not just the equipment purchase price.

This article explains the real cost drivers that global buyers must understand before making an egg tray factory investment.

1. Raw Material Availability: The Foundation of Production Cost

Raw materials typically account for 30–45% of total long-term egg tray production cost.

Common raw materials include:

- Old corrugated containers (OCC)

- Waste cartons

- Old newspapers

- Mixed recycled paper

In many regions, waste paper quality is inconsistent due to manual sorting and unstable supply chains. When raw material quality fluctuates, pulp loss increases and product strength becomes difficult to control, directly raising the overall egg tray manufacturing cost.

For factories operating in such conditions, investing in a robust pulping and screening system is far more cost-effective than choosing the lowest-priced forming machine.

2. Energy Structure: The Biggest Variable in Operating Cost

Energy consumption—especially in the drying stage—is often the largest ongoing expense in egg tray production.

Depending on the region, factories may rely on:

- Electricity

- Diesel

- Natural gas

- Biomass or waste heat

Drying system options include:

- Fully automatic metal drying lines

- Traditional brick kiln drying

- Hybrid drying systems

Drying system options include fully automatic metal drying lines, traditional brick kiln drying, and hybrid systems. While drying equipment is often included in the initial egg tray production line price, its long-term energy efficiency has a much greater impact on profitability than most buyers expect.

In markets with unstable or expensive energy supply, drying system selection matters more than forming speed.

3. Automation Level vs Local Labor Cost

Automation directly influences both initial investment and long-term operating expenses.

In regions with low labor costs, semi-automatic lines are often sufficient. In areas where wages are rising or labor availability is unstable, higher automation can significantly reduce long-term risk.

When evaluating an egg tray manufacturing line, buyers should calculate labor cost over a 3–5 year operating period, rather than focusing only on upfront equipment expenses.

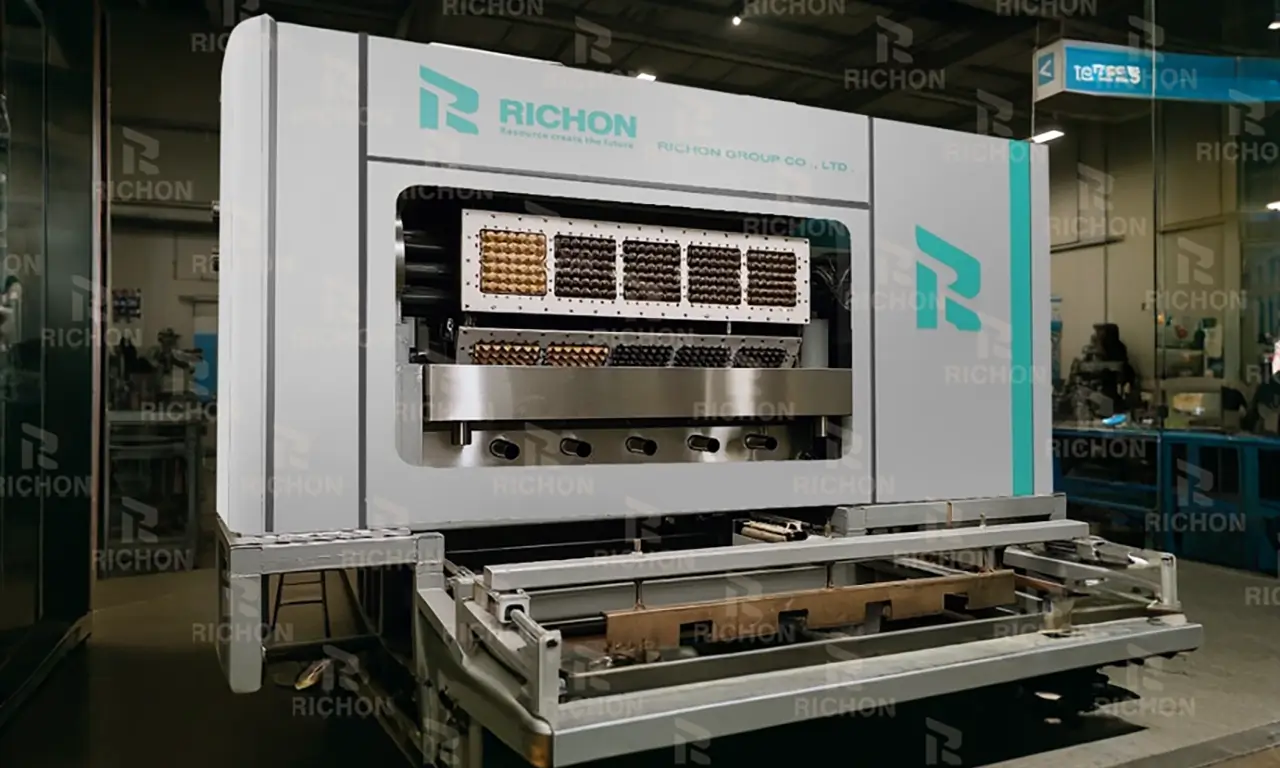

4. Machine Configuration: Why Similar Capacities Have Different Costs

Two production lines with the same rated output can show a significant difference in performance, reliability, and price.

Key configuration factors include:

- Servo-driven or hydraulic forming systems

- Vacuum efficiency and stability

- Mold material and precision

- Electrical components and safety standards

Lower-priced configurations may appear attractive at first, but often result in higher energy consumption, frequent maintenance, and inconsistent tray quality. Over time, these issues increase total egg tray manufacturing cost and reduce production stability.

Learn More About Our Egg Tray Production Lines

For readers looking to optimize production cost and efficiency, our complete Egg Tray Production Line integrates raw material preparation, forming, drying, and automation systems, helping factories achieve stable quality and predictable operating costs.

Explore Production Line Details5. Mold Design and Product Specification

Egg tray mold play a decisive role in determining product quality, reject rate, and daily output.

For export markets, egg trays must meet specific requirements such as:

- Uniform weight

- Strong edges

- Stable stacking

- Low deformation after drying

Poor mold design increases scrap rates and customer complaints, indirectly pushing up the real egg tray production cost even if the equipment price seems competitive.

6. Factory Infrastructure and Local Compliance

Factory infrastructure is often underestimated during budget planning.

Additional costs may include:

- Civil foundation and layout preparation

- Power transformer upgrades

- Water recycling and wastewater treatment

- Dust control and environmental compliance

These factors are rarely included in the initial egg tray machine price, but they are essential for stable operation and long-term compliance.

7. Installation, Training, and After-Sales Support

For overseas buyers, installation and technical support are part of the real production cost.

A production line without proper commissioning, operator training, and spare parts support may experience frequent downtime. In contrast, reliable after-sales service helps stabilize output and protects the overall egg tray factory investment.

Real Cost Breakdown Example (6,000 pcs/hour)

| Cost Item | Approximate Share |

| Equipment | 35–45% |

| Drying System | 20–30% |

| Factory Infrastructure | 10–15% |

| Energy System Setup | 8–12% |

| Training & Labor | 5–8% |

Final Thought: Focus on Cost per Tray, Not Machine Price

The real production cost of an egg tray production line is not defined by the purchase price, but by cost per 1,000 trays over time.

Energy efficiency, raw material adaptability, production stability, and technical support ultimately determine profitability. This is why experienced buyers look beyond the egg tray production line price and focus on long-term operating performance.

Smart investors do not ask:

“How cheap is the machine?”

They ask:

“How stable and predictable is my production cost over the next five years?”

Contact Us

Get in touch with our team for any inquiries about our egg tray machines and services.

Project Scope

Do you need a complete project solution or a partial solution? Our team can customize the perfect setup for your specific needs and budget constraints.

Product Expectations

What kind of finished product do you expect, and what quality standards are important to you?

Project Timeline

What is your expected timeline for project implementation and operation?

Budget Range

What is the approximate budget range for your project procurement?

Send Us Your Information

Accurate project information will help us provide the perfect solution for your needs.