How to Start a Waste Paper Recycling Egg Tray Project

Complete Guide to Egg Tray Production Line Setup and Pulp Molding Technology

Start a profitable business by turning waste paper into high-quality egg trays. Learn the full process: raw materials, pulping technology, forming systems, equipment selection, and ROI analysis.

1. Types of Waste Paper Used

Waste paper is the primary raw material for any pulp molding egg tray production line.

Common Raw Materials

- OCC (Old Corrugated Cartons)

- Office waste paper

- Newspapers and magazines

- Mixed paperboard

2. Recycling & Pulping Process

Key Processing Steps

- Sorting and impurity removal

- Hydrapulper pulping

- Screening and refining

- Water recycling

Egg Tray Production from Recycled Paper

Transform waste paper into biodegradable egg trays using pulp molding technology, capitalizing on the global shift toward eco-friendly packaging and sustainable manufacturing.

Step-by-step guide to maximize profits and efficiency in egg tray production

Automatic forming machine molding station for efficient egg tray production

High-Profit Opportunity in Waste Paper Recycling

Eco-friendly Packaging Demand

Recycling waste paper into egg trays is a lucrative business that meets the growing demand for sustainable packaging while reducing environmental waste.

- Reduces environmental pollution by reusing paper

- Low-cost raw materials with high availability

- Growing demand for biodegradable and green packaging

- High profit margins with efficient pulp molding equipment

The Paper-to-Tray Conversion Process

Step-by-Step Production

Pulp molding technology efficiently converts waste paper into durable egg trays, combining sustainability with high production quality.

- Pulping: Mixing waste paper with water to create a fiber slurry

- Forming: Precision molding machines shape the slurry into trays

- Drying: Drying ensures tray strength and durability

- Packaging: Ready-to-sell egg trays prepared for market distribution

Sustainability and Cost Efficiency

Energy-Saving Production

Using recycled paper reduces material costs and promotes eco-friendly operations. Pulp molding is an energy-efficient, cost-effective method for producing high-quality egg trays.

- Minimizes reliance on virgin paper materials

- Energy-efficient drying and forming process

- Supports the eco-conscious packaging market

Paper Pulp Molding Process Flow

From waste paper to finished egg trays in four key steps

Raw Material Preparation

Sorting and cleaning waste paper to ensure pulp quality

Pulping & Mixing

Hydrapulper converts paper into fiber slurry for molding

Molding & Forming

Precision machines shape the slurry into biodegradable egg trays

Drying & Finishing

Trays are dried and quality-checked before packaging

Raw Materials

Various types of waste paper ready for pulp molding

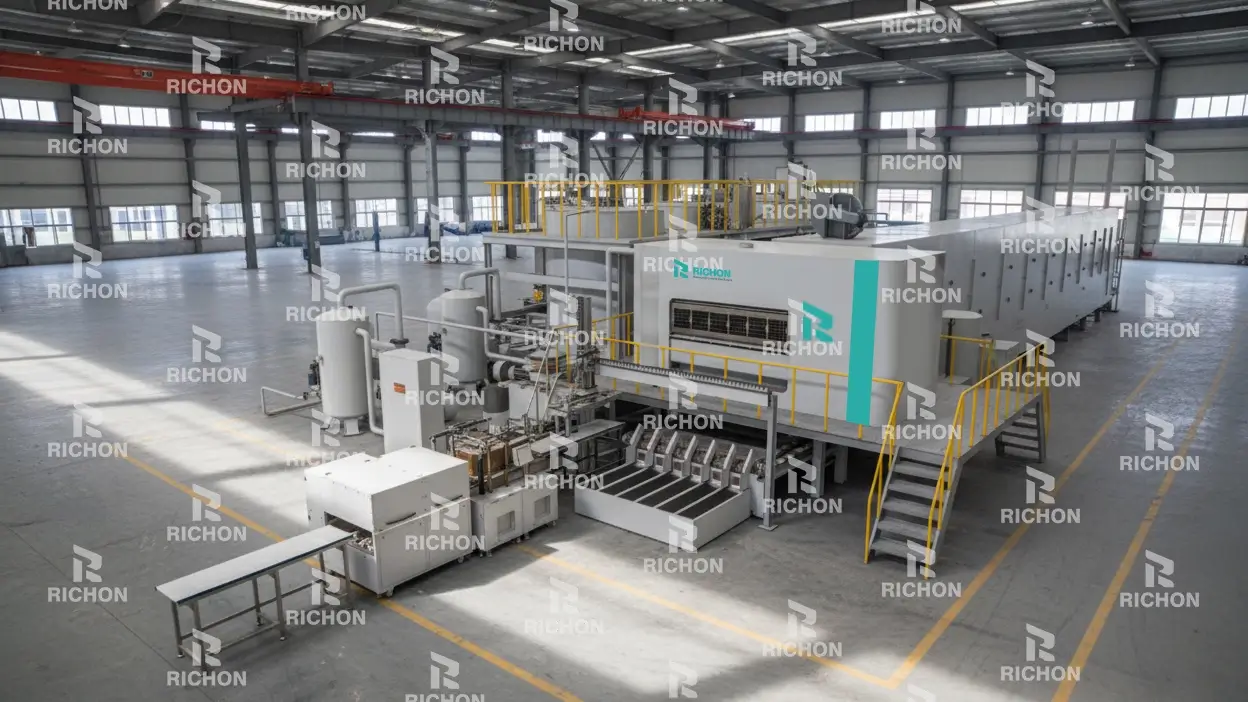

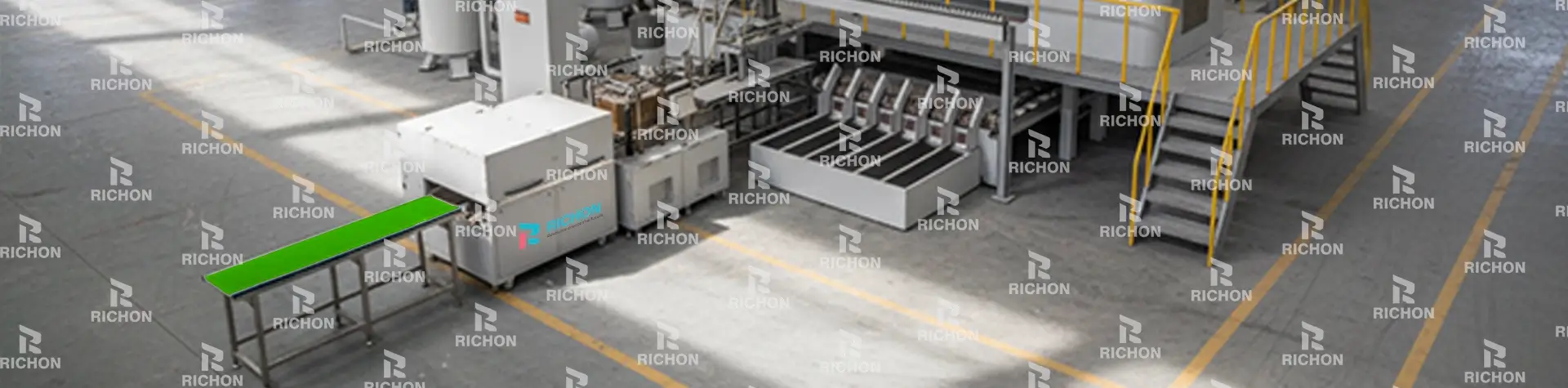

Production Line

Automated equipment ensures efficient egg tray production

Finished Products

High-quality biodegradable egg trays ready for market

Market Outlook: Eco-Friendly Packaging Replacing Plastics

Worldwide bans on single-use plastics, stricter environmental regulations, and increasing consumer demand for sustainable packaging are driving rapid adoption of biodegradable molded pulp products. Egg trays, fruit trays, pulp cup holders, and other eco-friendly packaging solutions are experiencing annual growth exceeding 15%, presenting profitable opportunities for investors and businesses in the green packaging industry.

The Shift to Sustainable Packaging and Waste Paper Recycling

Governments and corporations worldwide are implementing regulations to reduce plastic waste. As a result, molded pulp packaging is becoming a preferred solution for food and consumer goods industries.

The global molded pulp packaging market is projected to reach $7.5 billion by 2027 with a compound annual growth rate (CAGR) of 7.2%, driven by increasing demand for biodegradable egg trays, fruit trays, and pulp containers.

By integrating waste paper recycling into production, businesses can lower material costs, reduce environmental footprint, and tap into a rapidly expanding eco-friendly packaging market.

Key Investment Areas in Biodegradable Molded Pulp Packaging

Eco-Friendly Packaging Solutions

Biodegradable packaging for eggs, fruit, and consumer goods, compostable food packaging alternatives, and sustainable pulp packaging products are rapidly replacing single-use plastics.

Waste Paper Recycling & Raw Material Sourcing

Utilizing recycled paper for molded pulp production, low-cost sustainable raw materials, and circular economy waste paper solutions ensures profitability and environmental compliance.

Automated Egg Tray Production Lines

Deploying high-efficiency egg tray machines, energy-saving pulp molding equipment, and large-scale automated production lines guarantees consistent quality and output for the growing biodegradable packaging market.

High-Return Investment in Biodegradable Packaging Industry

With global plastic bans expanding and awareness of environmental sustainability increasing, now is the ideal time to invest in molded pulp production and eco-friendly packaging projects. Businesses that leverage waste paper recycling and modern automation can achieve cost efficiency, high profit margins, and long-term growth in this rapidly expanding industry.

Egg Tray Production Process and Equipment

Step-by-step guide to efficient egg tray manufacturing

A standard egg tray production line includes: Pulping → Molding → Drying → Packaging. Production capacity ranges from 2,000 to 6,000 pcs/h with semi-automatic or fully-automatic systems to meet different factory needs.

Pulping

Turning waste paper into high-quality pulp

Molding

Shaping pulp into sturdy egg trays

Drying

Controlled drying to ensure strength and durability

Packaging

Stacking and packaging trays for transport

Waste Paper Pulping System

Efficient pulp preparation

Mix waste paper with water to produce high-quality pulp suitable for molding egg trays. Ensures fiber quality and impurity removal.

- Hydrapulper for fast fiber separation

- High-consistency cleaner removes impurities

- Refining system adjusts pulp consistency

Egg Tray Molding System

Precision tray formation

Automated forming machines shape pulp into uniform egg trays with adjustable molds for different tray types.

- Automatic or semi-automatic forming machines

- High efficiency shaping process

- Adjustable molds for various tray types

Drying System

Moisture removal for durability

Controlled hot-air drying strengthens trays, ensures consistent quality, and improves energy efficiency.

- Hot-air drying system

- Precise time and temperature control

- Energy-efficient operation

Stacking and Packaging System

Efficient post-production handling

Dried trays are stacked and packed for shipment. Automation reduces labor and ensures safe transport.

- Automatic stacking and bundling

- Efficient packaging reduces manual work

- Custom packaging for tray sizes

Investment and ROI Analysis for Egg Tray Production

Cost, profit margin, and payback insights

Producing 10,000 egg trays/day requires $25,000–$80,000 depending on automation level. Expected gross margin ~30%, with payback period 8–12 months.

Production Line Cost

Includes machinery, setup, and raw materials:

- Semi-automatic low-investment systems

- High-capacity fully-automatic systems

- Setup and training costs

Profit Margins

Optimized systems achieve ~30% gross margin:

- Low-cost waste paper reduces cost

- Economies of scale improve profitability

- Automation ensures efficiency

Return on Investment (ROI)

Payback in 8–12 months:

- Depends on market demand

- Early ROI possible with high eco-friendly packaging demand

- Long-term stable profit with consistent production

Key Investment Metrics

Based on 10,000 trays/day:

Global Success Cases

Real-world examples of egg tray machine export and waste paper recycling projects delivered worldwide

We provide complete solutions for egg tray machine export and turnkey waste paper recycling project cases, supporting customers from installation to full production.

Successful Waste Paper Recycling Egg Tray Projects

Turnkey Solutions for Efficient Production

Our engineering team has helped clients across Africa, Southeast Asia, and South America establish efficient waste paper recycling systems and egg tray production lines. From equipment setup to on-site operational training, we ensure every factory runs smoothly and achieves sustainable local manufacturing.

- Turnkey egg tray production line installation

- On-site operational training and technical support

- Customized layout design for local conditions

- High-efficiency equipment for stable long-term production

Steps to Start Your Egg Tray Production Project

Follow this professional roadmap to launch your egg tray manufacturing business. From waste paper supply planning to machine installation and training, each step ensures efficient setup and long-term profitability.

1. Raw Material & Site Assessment

Waste Paper Sourcing & Factory Layout

Evaluate the availability of waste paper, land area, utilities, and workflow layout to build a scalable egg tray production plant with optimal efficiency.

2. Select the Right Equipment Model

Egg Tray Machine & Automation Level

Choose the right egg tray machine model, production capacity, and drying system. Implement automated egg tray production lines to match market needs and maximize ROI.

3. Production Line Installation

Setup & Commissioning

Our engineers complete full installation and commissioning to ensure smooth operation and efficient waste paper recycling from day one.

4. Training & After-Sales Support

Operation & Maintenance Guidance

Receive hands-on training for egg tray production, equipment maintenance, and long-term technical support—ensuring consistent productivity and profitable operations.

Contact Us

Get in touch with our team for any inquiries about our egg tray machines and services.

Project Scope

Do you need a complete project solution or a partial solution? Our team can customize the perfect setup for your specific needs and budget constraints.

Product Expectations

What kind of finished product do you expect, and what quality standards are important to you?

Project Timeline

What is your expected timeline for project implementation and operation?

Budget Range

What is the approximate budget range for your project procurement?

Send Us Your Information

Accurate project information will help us provide the perfect solution for your needs.